As industries evolve, so does the need for advanced machinery that can meet the growing demands of modern manufacturing processes. Among the many tools revolutionizing the metalworking sector, the latest pug cutting machines are at the forefront. Especially in the UAE, where metal fabrication and construction industries are booming, pug cutting machines are becoming indispensable tools in workshops.

This article explores why these advanced machines are essential for modern workshops, particularly those involved in steel fabrication machinery products in the UAE.

What is a Pug Cutting Machine?

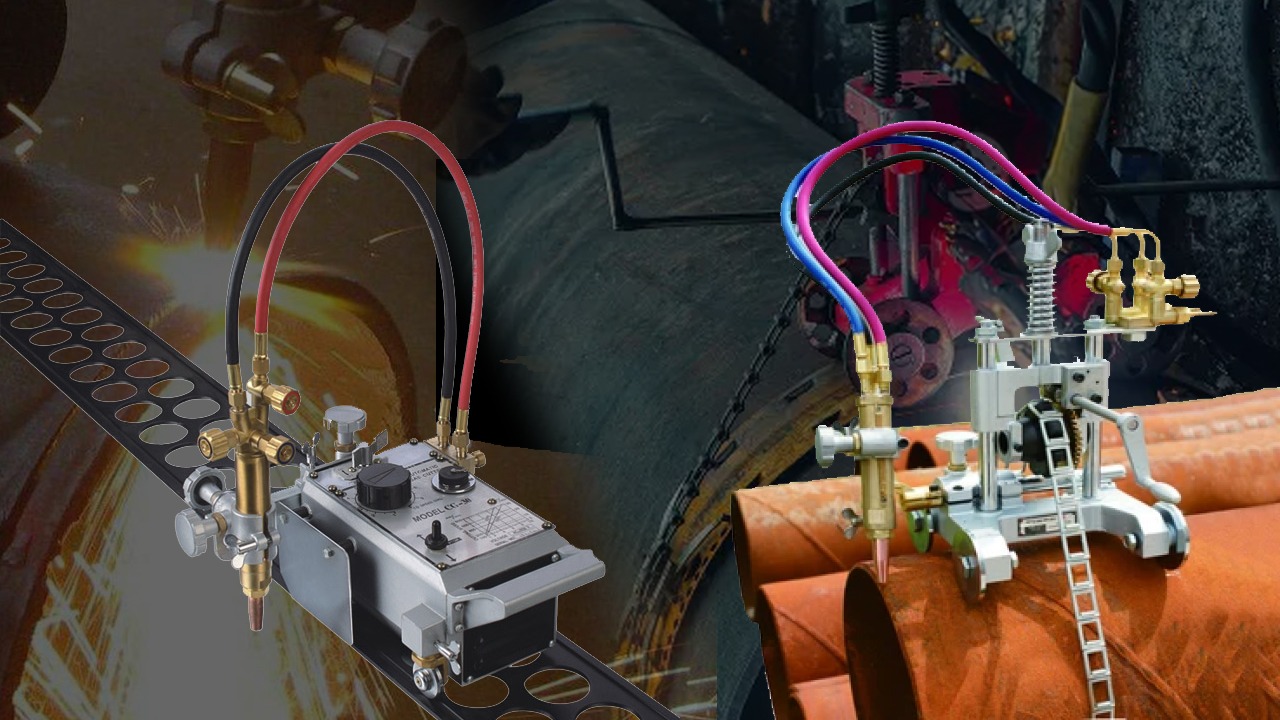

A pug cutting machine is a type of portable gas cutting equipment that is mainly intended for cutting steel and other metals. It is perfect for fabrication facilities, construction sites, and workshops because of its adaptability and simplicity of usage. These machines typically run on oxygen and acetylene or propane gas, providing a clean, precise cut. The “pug” in pug cutting refers to the mechanism of moving the torch along a guided path, ensuring uniformity in cutting shapes, especially for larger steel sheets or plates.

Why Pug Cutting Machines Are Vital for Modern Workshops

In any workshop, precision is key. Whether it’s for building structures, manufacturing parts, or creating steel components, the accuracy of cuts can determine the overall quality of the final product. The latest pug cutting machines in UAE offer unmatched precision due to their advanced design and integrated control systems. Modern pug machines come with adjustable torch angles, speed control, and track-guided systems, ensuring that each cut is identical to the last. This consistency is vital for workshops dealing with large volumes of steel fabrication, ensuring high standards of quality.

1. Increased Efficiency and Speed

Time is money in any industry, and modern pug cutting machines are designed to maximize productivity. Traditional manual cutting processes can be labor-intensive and time-consuming. However, the automated nature of today’s pug cutting machines means they can handle larger workloads faster, with minimal manual intervention.

The ability to produce clean cuts without extensive preparation or post-cut finishing saves valuable time for workers. This enhanced efficiency makes pug cutting machines a top choice for workshops involved in steel fabrication machinery products in UAE, where meeting project deadlines is crucial.

2. Versatility in Applications

One of the main advantages of pug cutting machines is their versatility. These machines are not only used for straight-line cutting but can also cut complex shapes with ease. Whether your workshop is cutting steel sheets for construction, creating components for machinery, or fabricating custom metal parts, a pug cutting machine can handle the task.

In industries like shipbuilding, heavy equipment manufacturing, and steel construction—common in the UAE—pug cutting machines provide the flexibility to work with different metal thicknesses and shapes. They are an essential equipment for every modern workshop because of their versatility.

3. Cost-Effectiveness

Investing in the latest pug cutting machines in UAE can significantly reduce operational costs. The precision and speed of these machines reduce material wastage, as cuts are clean and uniform, minimizing the need for rework. Furthermore, their ability to automate many aspects of the cutting process means workshops can save on labor costs.

In a competitive market like the UAE’s industrial sector, keeping operational costs low while maintaining high-quality output is essential. By incorporating pug cutting machines, workshops can boost their profitability through increased production efficiency and reduced waste.

4. Enhanced Safety Features

Modern pug cutting machines come equipped with advanced safety features that make them safer to operate than their older counterparts. Automatic shut-off systems, gas flow regulators, and ergonomic designs all contribute to reducing the risk of accidents. Safety is paramount in any workshop, and investing in machines with built-in safeguards ensures that workers can operate them confidently.

In workshops where cutting steel plates or sheets is a regular task, the new safety features not only protect employees but also ensure that projects are completed on time without the risk of accidents causing delays.

Applications of Pug Cutting Machines

Large-scale infrastructure projects in the UAE are well-known, and include skyscrapers, bridges, and industrial facilities. As a result, the demand for steel fabrication machinery products in UAE has grown significantly. Pug cutting machines play a vital role in this landscape due to their ability to handle the heavy-duty requirements of steel cutting.

- Construction Industry: From cutting steel beams to plates used in the construction of buildings and bridges, pug cutting machines ensure precision and reliability in every cut.

- Shipbuilding: In shipyards, pug cutting machines are used to cut steel plates for ship hulls, bulkheads, and other components, ensuring that each part fits perfectly.

- Heavy Equipment Manufacturing: In industries producing large machinery, pug cutting machines are employed to create the metal components needed for assembly.

- Custom Fabrication: Workshops involved in producing custom metal parts for various industries also benefit from pug cutting machines, as they allow for detailed, intricate cuts with minimal setup time.

As the demand for quality and efficiency in metalworking continues to rise, Rockwood Machinery offers the latest pug cutting machines in UAE have proven to be essential machines in modern workshops. Their precision, versatility, cost-effectiveness, and safety features make them a valuable investment for any workshop involved in steel fabrication machinery products in the UAE. By integrating these machines into daily operations, workshops can increase productivity, reduce costs, and deliver high-quality results, making them indispensable in today’s competitive industrial landscape.

To read more, click: Short-Term Projects? Here’s Why You Should Consider Industrial Machinery Rentals in UAE