Welded studs are essential in the fields of industrial manufacturing and building. These little but powerful parts are crucial for maintaining longevity, enabling accuracy, and securing structures. For businesses and professionals, finding reliable welded studs suppliers in UAE and understanding the versatility of these studs is essential for achieving project success. Furthermore, the option of industrial machinery rentals offers affordable solutions to a range of industrial requirements.

What Are Welded Studs?

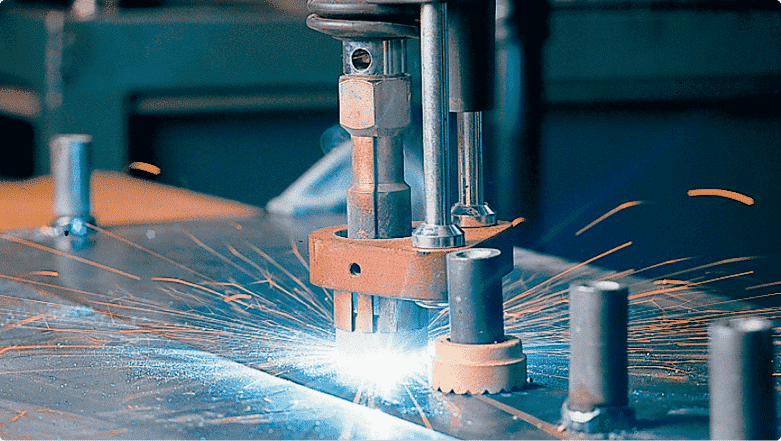

Essentially, welded studs are cylindrical fasteners with a threaded end. Usually, high-strength materials including alloy steel, carbon steel, and stainless steel are used in their manufacture. The unique feature of these studs lies in their application: they are welded directly to the base material using specialized welding techniques like arc welding or resistance welding.

Types of Welded Studs

Understanding the different types of welded studs available is essential for selecting the right component for specific applications. Below are the primary types:

- Threaded Studs

- Features: Threaded studs have external threads, allowing nuts or other fasteners to be attached.

- Uses: Commonly used in construction for securing structures, automotive components, and machinery installations.

- Shear Connectors

- Features: The purpose of shear connectors in composite construction is to transfer shear force between concrete and steel.

- Uses: Ideal for bridge construction, decking, and high-rise buildings.

- Deformed Bar Anchors (DBAs)

- Features: A textured surface is featured to enhance grip with concrete.

- Uses: Widely employed in precast and cast-in-place concrete applications.

- Insulation Pins

- Features: Used for attaching insulation materials to metal surfaces.

- Uses: Popular in HVAC systems, industrial ovens, and energy-efficient buildings.

- Capacitor Discharge (CD) Studs

- Features: Smaller in size and welded using capacitor discharge methods.

- Uses: Suitable for lightweight applications like electrical enclosures and panels.

- Flanged Studs

- Features: Feature a flanged head for added surface area and stability.

- Uses: Perfect for use in applications requiring extra load distribution.

Common Applications of Welded Studs

Because of its strength and adaptability, welded studs are used in a variety of industries. Here are some of their primary uses:

- Construction Industry

- Welded studs are indispensable in composite construction, enabling the seamless integration of steel and concrete. Shear connectors, for instance, provide structural integrity to bridges and buildings.

- Automotive Industry

- Threaded and CD studs are extensively used in manufacturing vehicles, ensuring components like panels and engines are securely fastened.

- Shipbuilding

- Stud welding is widely employed in shipbuilding for attaching insulation, securing components, and enhancing the vessel’s structural stability.

- Electrical and Electronics

- Capacitor discharge studs are crucial for assembling electrical panels, enclosures, and circuit boards.

- Energy Sector

- Applications for welded studs in renewable energy include solar panel mounting systems and wind turbine installations.

Choosing the Right Welded Studs and Machinery Rentals

For businesses in the UAE, partnering with Rockwood Machinery is a smart choice for sourcing high-quality welded studs and accessing industrial machinery rentals.

Here’s why:

- Product Variety: Ensure the supplier offers a wide range of welded studs to meet diverse project needs.

- Quality Assurance: Look for suppliers that provide dependable and long-lasting parts while adhering to global standards.

- Technical Support: A good supplier offers expert advice on selecting the right studs and their applications.

- Timely Delivery: Choose a supplier known for prompt delivery to avoid project delays.

Industrial Machinery Rentals in UAE: A Cost-Effective Solution

Alongside sourcing welded studs, businesses in the UAE can benefit significantly from Industrial Machinery Rentals offered by Rockwood Machinery. By removing the need for significant upfront costs, renting equipment provides flexibility and access to cutting-edge technologies without the hassle of ownership.

Key benefits of renting industrial machinery include:

- Cost Savings

- Renting equipment reduces upfront expenses, it’s a good choice for businesses with budget constraints.

- Access to Advanced Technology

- Keep up with the most recent technological advancements without having to upgrade frequently.

- Flexibility

- Rent machinery for specific projects or time frames, avoiding idle equipment and maintenance expenses.

- Expert Support

- Many rental providers offer technical support, ensuring the equipment is operated efficiently.

Conclusion

Welded studs are essential components for many different industries, providing strength, durability, and versatility. For businesses in the UAE, partnering with reliable welded studs suppliers like Rockwood Machinery is essential to meet project demands efficiently. Additionally, leveraging Industrial Machinery Rentals through Rockwood Machinery offers a cost-effective way to access advanced equipment, enhancing productivity and reducing operational costs.

Whether you’re involved in construction, manufacturing, or marine applications, choosing the right supplier and rental service provider can significantly impact your project’s outcome.

To know more, click: How to Choose the Right Magnetic Lifters in UAE: A Buyer’s Guide