As suggested by its name, stainless steel is a material resistant to stain and rust. Due to this property, stainless steel is widely utilized across various industries such as construction, manufacturing, and food and beverage. Stainless steel can be welded into numerous equipment—including machine parts, pipes, stainless steel frames, utensils, plates, and containers—but welding stainless steel requires precision and knowledge to maintain its distinct characteristics. This blog will detail the specifics of cleaning welded stainless steel, including the makeup of stainless steel, the best welding processes, the benefits and drawbacks of using stainless steel weld cleaning machines, and methods to ensure your weld will last—especially when welding with a stainless steel weld cleaning machines in UAE.

What is Stainless Steel?

Stainless steel is fundamentally an iron alloyed with chromium, nickel and other materials depending on the grade of stainles steel. The important aspect is its makeup from chromium, which develops a protective element on the surface that makes it resistant to corrosion, stain, and rust.

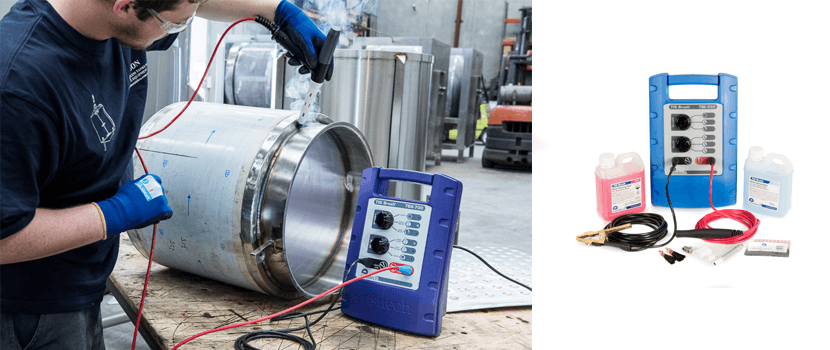

However, during the welding process, it’s the protective oxide that is compromised, resulting in discoloration, oxidation, and corrosion. This is where stainless steel weld cleaning machines help, electrically polishing or cleaning the welded surfaces to restore the protective element.

Types of Welding Recommended for Stainless Steel

Using the right welding process is key to developing a strong, lasting weld when welding stainless steel. The two most common welding processes for stainless steel are Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding.

TIG Welding

The TIG welding process, uses a non-consumable tungsten electrode which gives a precise weld with a clean weld. This is ideal when welding thinner pieces of stainless steel. With TIG welding, an operator can better control the heat input and is less likely to distort the steel.

MIG Welding

MIG welding uses a consumable wire electrode and is more often the preferred process when welding thicker stainless steel material. MIG welding is the faster of the two processes and is often preferred for larger or less detailed projects.

Regardless of the welding process, post-welding cleaning is vital to removing heat tint and restoring corrosion-resistant surfaces.

The Pros and Cons of Stainless Steel Weld Cleaning Machines

Although the welding process is very important, post-cleaning is as important as well when regarding the aesthetics and sustainability of the structure being welded out of stainless steel. Using a stainless steel weld cleaning machine in UAE comes with its own set of benefits and challenges.

Pros

✅ Restores Corrosion Resistance

Good weld cleaning machines remove the oxide layer and heat tint on the welded stainless steel, allowing for the metal to re-passivate to retain its corrosion-resistant characteristics.

✅ Aesthetic Improvement

Post welding there may be discoloration or staining that takes away from aesthetically pleasing welded stainless steel structures. A weld cleaning machine restores the original polished finish to the weld.

✅ Safe and Environmentally Friendly

Modern wet cleaning machines use non-toxic, environmentally-friendly electrolytic fluids, which the user can safely handle and dispose of unlike previous methods of cleaning stainless steel welds using hazardous pickling pastes.

✅ Fast and Efficient

Manual cleaning using an abrasive or chemical is inefficient and takes too much time. A weld cleaning machine will clean quickly and consistently, which increases productivity.

Cons

❌ Initial Investment Cost

High-quality stainless steel weld cleaning machines can be expensive initially. But, the savings through labor, chemical costs, and corrosion failures in the long run will outweigh the original investment.

❌ Operator Training Required

Operator training is necessary so that the welding cleaning machines can be utilized properly. Improper operation can lead to inefficient cleaning or damage to the surface.

❌ Limited Use on Certain Surfaces

Weld cleaning machines are great for flat surfaces and average welds, but some will have difficulty cleaning intricate geometries or welds that are not accessible.

Best Practices for Welding & Cleaning Stainless Steel

Following best practices, during and after the welding of stainless steel, helps you get the best performance, longevity and aesthetic appeal. Here are some suggestions:

🔹 Use Clean Materials

Contaminants such as greasy hands or dust can jeopardize both the quality of the weld and the corrosion resistance. Always make sure the weld is clean before welding.

🔹 Control Heat Input

Stainless steel is sensitive to high heat. Controlling heat input will help reduce warpage and excessive oxidation during the welding of stainless steel.

🔹 Select the Right Filler Metal

Always use filler metals compatable with the grade of base stainless steel you are working with, in order to maintain the corrosion resistance and strength of the welded joint.

🔹 Apply Post-Weld Cleaning

Use a stainless steel weld cleaning machine in the UAE immediately after the weld to post-treatment the weld joint. This will oxidize and discolor the weld, and it will also passivate and restore the corrosion resistance to the joint.

🔹 Use Proper Electrolytic Solutions

It is prefered to use quality, pH neutral cleaning solutions in the weld cleaning machines. These have been proven to be safer and more effective for restoring stainless steel surfaces.

Why Weld Cleaning is Essential for Stainless Steel Structures

For end user in industries like food processing or pharmaceuticals and in marine environments, cleanliness and corrosion resistance are of utmost importance. Aside from the unprofessional appearance of a discolored weld during construction, a once-dressed weld might become a future site of localized corrosion which could cause dire consequences if not treated properly. Efficient stainless steel weld cleaning machines help companies maintain cleanliness and health and safety practices, as well as aesthetic appearance and longevity of equipment and structure.

Need an Insulation Pin Supplier in the UAE to co-ordinate with your weld? Rockwood Machinery has everything you need: from welding consumables including insulation pins, cleaning and pre-cleaning products, and our full line of weld cleaning machines, you will find everything you are looking for with Rockwood Machinery.

Get the Best Stainless Steel Weld Cleaning Machines

As with all expert welders, welding stainless steel requires more than a skilled operator; again, it also requires post-weld care. We are not here to tell you what to do – just how to get the best out of the machines we take part in the sale of. Whether you purchase a machine from us or not, we want to help you with any questions you have about using machines for effective post-weld care.

As a trusted insulation pin supplier in the UAE, Rockwood Machinery understands and appreciates the importance of quality, safety, and productivity (efficiency) in your metalworking. In all the different trades, including construction, shipbuilding, and food processing, we try our best to be the trusted insulation pin supplier in the UAE with the right machines and attachments for your trades.

Get in touch with us today for additional information on our variety of stainless steel weld cleaning options and other fabrication essentials. We want to help you improve productivity and provide the best possible quality in every weld.

To continue reading, click: How Laser Cutting Machines are Transforming the Agricultural Machinery Industry