BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

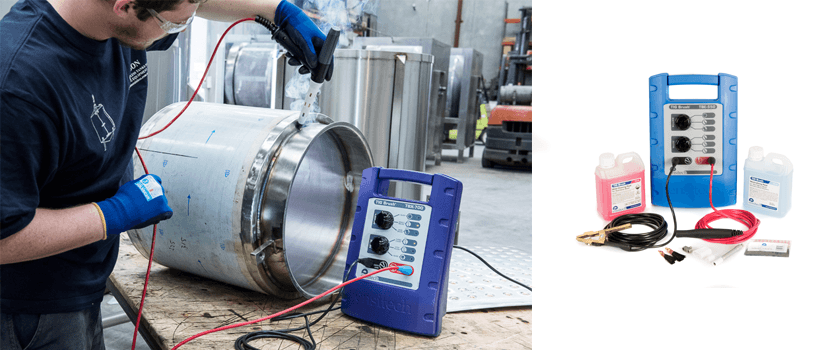

Tig Brush Cleaning Machine in UAE

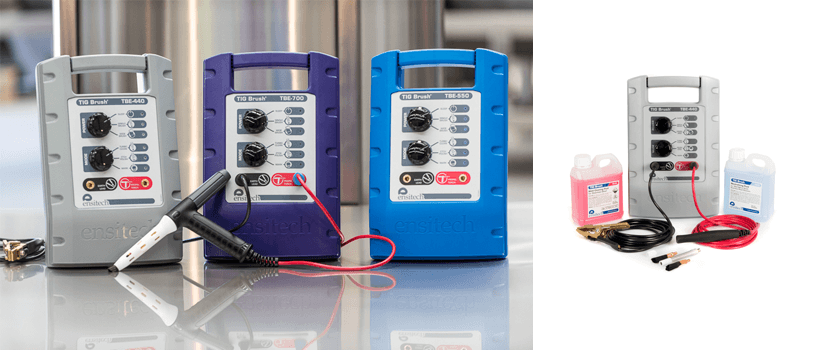

We represents Ensitech the world’s premium stainless steel weld cleaning system from Australia. Offered in the brand name of “ TIG Brush weld cleaning system ” creates a unique combination of electricity, heat and chemistry to deliver superior results in weld cleaning and metal surface finishing.

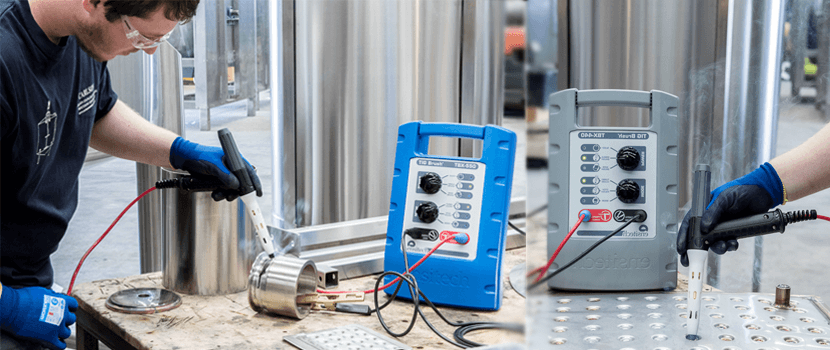

The TIG Brush Stainless Steel Weld Cleaning System employs an exclusive blend of electricity, heat, and chemistry to achieve outstanding outcomes in both weld cleaning and the finishing of metal surfaces. Its exclusive conductive brush administers cleaning solution to the work surface, generating a rapid and efficient electro-chemical cleaning process. This patented technology optimizes the transfer of heat to the work surface, guaranteeing top-notch performance even under challenging working conditions.

Its main features :

- No more pickling paste

- Works on all thicknesses

- 110V/240V auto-switching

- Low running costs

- Flexible & robust

- 100% duty cycle

How does it work?

The TIG Brush comprises a brush through which an electric current is passed. The brush is dipped into a cleaning fluid and then applied to the areas to be cleaned. The fluid is designed to remove the iron oxide marks which result from welding. The brush is designed to convert the electric current to high temperatures, especially at the end of the bristles. While the fluid is quite benign at room temperatures, the brush heats the fluid to an elevated temperature, when it becomes much more re-active. This results in an accelerated chemical action at the surface of the Stainless Steel.

Unlike Pickling Paste, the active ingredients of the cleaning fluid are not inherently dangerous to operator health, and if used correctly the fluid is non-toxic to the environment.

The Chemical Action

The blue and brown marks which result from welding are ferrous and ferric oxides of iron. Iron oxide layers are quite weak, and the temperature at which the TIG Brush operates quickly breaks down the iron oxides. The resulting ferric ions enter into solution in the fluid, where they are sequestered (held so they cannot form oxides again). When the TIG Brush is removed from the work and the fluid wiped away, the surface of the stainless steel is left free from ferric ions and oxides.

Surface Improvement (passivation)

Iron Oxides are not very good at protecting the metal surface from contamination, and for this reason any dis-coloured areas start to corrode soon after welding, even after they have been cleaned. To stop this corrosion the metal surface needs to be “passivated”. When the TIG Brush removes the iron oxide layer, chromium rich metal underneath is exposed. The high temperature of the TIG Brush causes the chromium to rapidly oxidize, forming a Chromium Oxide layer in the place of the Iron Oxide layer. The process of forming the Chromium Oxide layer is called “passivation”.

Chromium Oxide is very good at protecting the underlying metal from contamination, and will limit corrosion and rusting. The Chromium Oxide layer is clear, so the original surface texture and appearance of the metal is maintained.