Circle Burner And Nozzle Welders

- Home / Products / Welding Automation / Circle Burner And Nozzle Welders

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

Circle Burner and Nozzle Welders in UAE

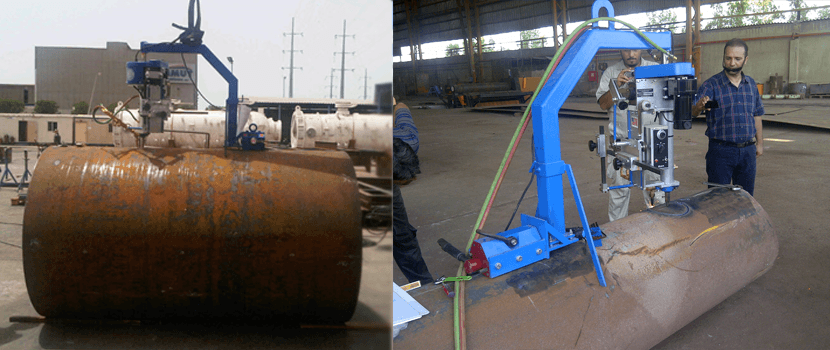

NOZZLE BURNER

Circle burners are used to make nozzle opening on the pressure vessels / and straight /beveled holes in large diameter pipes. Oxy-Flame circle burners from CWI manufactures can cut from 1 ½” to 42″ diameter beveled holes and 4″ to 42″ square cut holes (straight through no bevel) with the movement controlled by a mechanical cam which can be set prior to the cutting process. This cam setting depends on the vessel diameter and the nozzle diameter and can also be easily calculated by a mathematical formula. This has a rise and fall cam of 0 to 7 inches. Explore our high quality Circle burners and Nozzle welders in UAE at affordable rate.

The machine can be very easily set up on the vessels as it comes with a magnetic base which has on and off switch. The center pointer of the machine is placed on the center of the nozzle hole to be cut and the magnet is locked in position holding the machines onto the vessel surface. Then the torch is positioned manually to the desired diameter. The cam is then set based on the chart value by adjusting the cam adjustment screw. The machine is then switched on keeping the knob in the forward/reverse direction and then the torch runs along the diameter of the hole by automatically adjusting its height to the change in vessel curvature.

The circle burner can do bevelling also, the torch tip is adjustable to any angular position, there is an angle graduation scale near the tip and bevelled holes can be cut. The max cutting thickness depends on the nozzle employed.

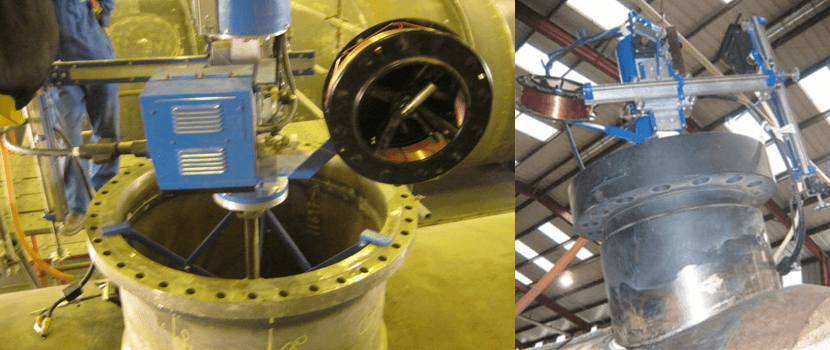

CIRCLE WELDER

Like the nozzle burner , circle welder movement is also automatic and is controlled by mechanical cam which can be set prior to the welding process.

The nozzle welders adjusts to the tank curvature by means of the same cam motion and it has the rise and fall cam of 0 to 7” like the burner. The Nozzle welder but sits on the nozzle by the help of 3 jaw spider chucks. There are 3 different sizes of chucks which we had offered as options. The spider jaws of the chuck expands by a simple manual rotation fixing itself to the nozzle. The welder is then bolted to the chuck table.

There basically 3 different models of Nozzle welders, RW 1500, RW 1700 and RW 2000. These models differ from each other on basis of the nozzle dia capability that it can handle and the amps rating which determines the welding wire dia which these machines can handle. The nozzle welders can do Sub Arc , Mig or FCAW and derives power direct from the welding power source by connecting to its auxillary point. The most commonly used power sources are Lincoln , Miller and Esab with our welders.

The best part of Nozzle welders are that this machines automises and helps to do sub arc welding of nozzles. A thick walled nozzle for examble of 50 or 60 mm thk will require 2 Mig welders welding it manually for 2 to 3 days and then there are always chances for welding defects. Whereas here by doing sub arc welding with our nozzle welders, the entire nozzle can be done in half a day and gives the best weld quality as it is Sub Arc welding.

Also our nozzle welder has the wire spool holder and all the basic controls which are present on the sub arc welding power source so that the operator can control the feed , current and other parameters by adjusting it on the nozzle welder itself without moving down to the power source.