Are you looking for the best cutting machines in UAE? Finding the best cutting machine suppliers and dealers in the UAE requires a strategic and thorough approach. By leveraging online resources, industry events, and thorough evaluations, businesses can identify reliable partners that align with their specific needs and contribute to the success of their operations. Businesses seeking reliable cutting machines often face the challenge of identifying trustworthy suppliers and dealers. This blog explores effective strategies to find the best cutting machine suppliers and dealers in the UAE.

- Define Your Requirements: Before embarking on the search for suppliers, it’s essential to clearly define your cutting machine requirements. Understand the type, capacity, and specifications needed for your specific industrial applications.

- Online Directories and Platforms: Utilize online directories and platforms dedicated to industrial machinery. Websites and platforms that aggregate suppliers and dealers in the UAE can provide a comprehensive list of potential partners.

- Industry Networks and Exhibitions: Attend industry-specific exhibitions, trade shows, and networking events in the UAE. These gatherings serve as valuable platforms to connect with cutting machine suppliers, witness product demonstrations, and assess the latest technologies.

- Local Business Directories: Explore local business directories that list industrial equipment suppliers and dealers. These directories often provide contact information, company profiles, and customer reviews, aiding in the selection process.

- Check Credentials and Certifications: Verify the credentials and certifications of potential suppliers. Reputable dealers often adhere to industry standards and possess certifications that attest to the quality and reliability of their products.

- Customer References and Testimonials: Request customer references and testimonials from prospective suppliers. Hearing about the experiences of other businesses that have procured cutting machines from the same supplier can offer valuable insights.

- Evaluate After-Sales Support: Assess the after-sales support offered by suppliers. A reliable supplier provides not only quality machinery but also comprehensive support, including maintenance, repairs, and technical assistance.

- Compare Prices and Terms: Obtain quotes from multiple suppliers and compare not only the prices but also the terms of the agreement. Consider factors such as warranties, delivery times, and payment terms to make an informed decision.

- Visit Showrooms and Facilities: Whenever possible, visit the showrooms and facilities of shortlisted suppliers. A firsthand look at the manufacturing processes, product quality, and overall infrastructure can help in making a more informed choice.

- Negotiate and Establish Long-Term Partnerships: Engage in negotiations with potential suppliers and aim to establish long-term partnerships. Clear communication and mutual understanding contribute to a successful and sustainable business relationship.

Two distinct yet impactful cutting technologies: CNC plasma cutting and pug cutting machines.

CNC Plasma Cutting Machines: CNC (Computer Numerical Control) plasma-cutting machines are a technological marvel in metal fabrication. They utilize a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials with precision.

- Working Principle: The process involves a plasma torch, which creates a focused and high-temperature plasma arc. This arc melts through the metal, while a controlled stream of gas blows away the molten material, leaving a clean and precise cut.

- Applications: CNC plasma cutting machines are ideal for cutting intricate shapes in various materials, including steel, aluminum, and stainless steel. They find applications in industries such as automotive, construction, and metal artwork.

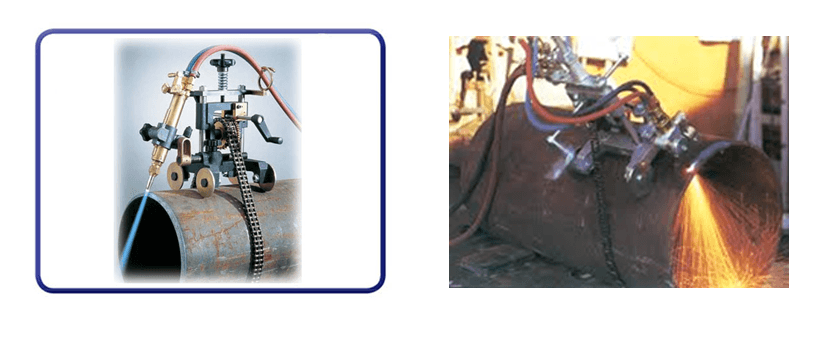

Pug-Cutting Machines: Pug-cutting machines, also known as profile gas-cutting machines, are versatile tools used for the thermal cutting of metal sheets in straight or beveled patterns.

- Working Principle: Pug-cutting machines use a gas flame to heat the metal to its ignition temperature. Simultaneously, a stream of oxygen is directed at the heated area, causing the metal to oxidize and form slag. The slag is then blown away by the force of the oxygen stream, resulting in a precise cut.

- Applications: Pug-cutting machines are employed in heavy industries, shipbuilding, and construction for cutting thick metal plates and profiles. They are particularly effective for producing straight cuts with smooth edges.

Key Differences:

- CNC plasma cutting offers a higher level of precision and is suitable for intricate designs while pug-cutting machines are adept at handling thicker metal plates with straight cuts.

- CNC plasma cutting is computer-controlled, allowing for automated and complex cutting patterns, whereas pug cutting involves manual guidance of the torch for more straightforward cuts.

- The choice between the two depends on the specific requirements of the project, considering factors such as material thickness, design complexity, and automation needs.

CNC plasma cutting machines and pug cutting machines stand out as reliable solutions for achieving precision in cutting. Whether it’s the intricate contours of CNC plasma or the robust simplicity of pug cutting, these technologies continue to shape industries and contribute to the evolution of metalworking processes.

CNC pug cutting machines, equipped with computerized numerical control, are gaining popularity among manufacturers in the UAE for their unmatched precision in shaping and profiling metal plates. The adoption of these machines is on the rise as they enable streamlined operations, offer technological advancements, and enhance efficiency in a competitive market. With a blend of advanced automation and cutting-edge technology, these CNC pug-cutting machines are transforming industrial metal-cutting tools, contributing to operational optimization, reducing labor costs, and minimizing errors across heavy industries in the UAE.

To know more about Pipe & Plate Beveling Machines: Advantages & Applications