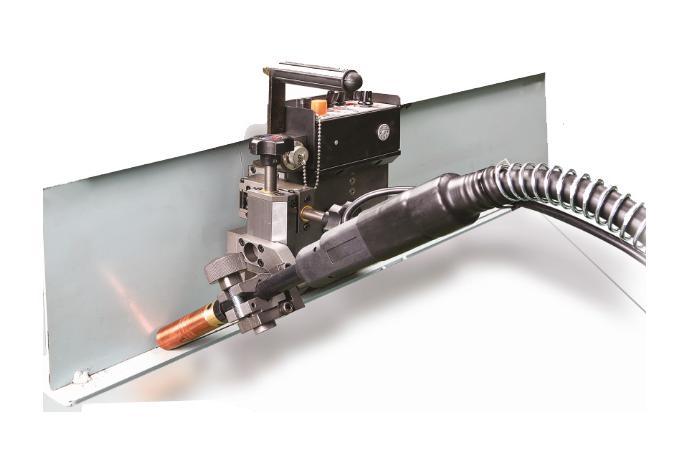

Fillet stitch and continuous welders play a crucial role in various welding applications, offering lightweight and precise welding capabilities. In the dynamic industrial landscape of the UAE, these tools find extensive use across industries such as shipbuilding, oil and gas, construction, and manufacturing. This blog explores the importance, uses, and applications of fillet stitch and continuous welders in the UAE’s industrial sector.

Importance of Fillet Stitch and Continuous Welders: Fillet stitch and continuous welders are valued for their:

- Lightweight design, enabling portability and ease of use.

- Precision welding capabilities, ensuring accuracy and consistency.

- Enhanced efficiency, leading to increased productivity and cost savings.

- Versatility, allowing for the welding of various materials and thicknesses.

Uses of Fillet Stitch and Continuous Welders: These welders are commonly employed in:

- Metal fabrication for joining components such as sheet metal, pipes, and structural elements.

- Automotive manufacturing for welding vehicle frames, chassis, and body panels.

- Construction projects for welding structural steel components and reinforcing bars.

- Aerospace manufacturing for welding aircraft components and assemblies.

Applications in the UAE: In the UAE’s industrial landscape, fillet stitch and continuous welders find diverse applications:

- Shipbuilding: Used for welding ship hulls, decks, and marine structures with precision and efficiency.

- Oil and Gas: Employed in welding pipelines, storage tanks, and equipment for offshore and onshore operations.

- Construction and Infrastructure: Utilized for welding steel structures, bridges, and buildings in ongoing projects.

- Manufacturing: Integral to metal fabrication, automotive, aerospace, and other manufacturing industries for diverse welding requirements.

Fillet stitch and continuous welders are indispensable tools in the UAE’s industrial sector, offering lightweight precision for a wide range of welding applications. Their importance spans industries such as shipbuilding, oil and gas, construction, and manufacturing, contributing to the country’s industrial growth and development. With their advanced capabilities and versatility, these welders continue to play a vital role in driving efficiency and innovation in welding processes across the UAE.

Rockwood Machinery stands out as a premier supplier of welded studs in UAE, offering high-quality products and exceptional services to meet the diverse needs of its customers. With a commitment to excellence and innovation, Rockwood Machinery has established itself as a trusted partner for welding solutions in various industries across the UAE.

Product Range: Rockwood Machinery offers a comprehensive range of welded studs, including:

- Shear Connectors: Used in composite steel-concrete structures to transfer shear forces between the steel beam and concrete slab.

- Arc Studs: Designed for welding onto flat surfaces or in through-deck applications to create a connection point for various fixtures and equipment.

- Threaded Studs: Ideal for use in applications requiring a secure threaded fastening point, such as in construction and manufacturing.

- Capacitor Discharge (CD) Studs: Utilized for rapid welding onto thin gauge materials without distortion or burn-through.

Quality Assurance: As a leading welded studs supplier, Rockwood Machinery prioritizes quality assurance at every stage of the manufacturing process. The company adheres to stringent quality control measures to ensure that its products meet international standards for performance, durability, and reliability. Each welded stud undergoes rigorous testing to verify its mechanical properties, weldability, and dimensional accuracy, guaranteeing superior quality and consistency.

Applications: Rockwood Machinery’s welded studs find wide-ranging applications across various industries in the UAE, including:

- Construction: Used in structural steel framing, concrete reinforcement, and composite steel-concrete construction projects.

- Automotive: Employed for welding onto vehicle frames, chassis components, and body panels in automotive manufacturing processes.

- Shipbuilding: Utilized in ship hull construction, deck fabrication, and marine equipment assembly for maritime applications.

- Industrial Manufacturing: Integrated into machinery, equipment, and infrastructure components requiring secure and reliable fastening solutions.

Customer Satisfaction: Rockwood Machinery is committed to customer satisfaction, offering tailored solutions, timely delivery, and responsive technical support to meet the unique requirements of its clients. With a team of experienced professionals and state-of-the-art manufacturing facilities, the company strives to exceed customer expectations and build long-term partnerships based on trust and reliability.

As a leading welded studs supplier in the UAE, Rockwood Machinery sets the benchmark for excellence in product quality, innovation, and customer service. With its comprehensive product range, stringent quality assurance processes, and commitment to customer satisfaction, Rockwood Machinery continues to be the preferred choice for welded studs solutions across diverse industries in the UAE.

To know more about Revolutionizing Material Handling: The Power of Material Magnetic Lifters in UAE