In the fast-evolving world of manufacturing, staying ahead of the competition requires investing in the latest technologies that can streamline operations, improve precision, and enhance overall efficiency. One of the most useful inventions for companies trying to optimize their workflows is the laser cutting machine. For businesses in the UAE, where the manufacturing sector is booming, the adoption of these machines is becoming increasingly popular. Let’s explore how laser cutting machines can be a game-changer for your business.

What Are Laser Cutting Machines?

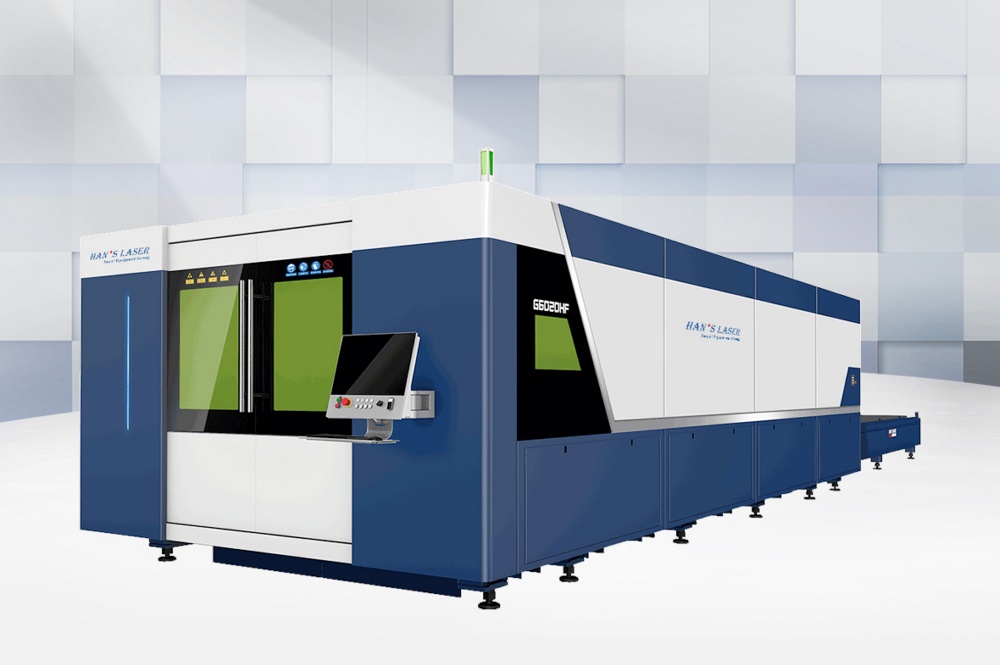

Laser cutting machines use a concentrated beam of light, known as a laser, to cut, shape, and engrave various materials. These machines are adaptable equipment for producers in a variety of industries since they can handle a broad range of materials, such as steel, plastic, wood, and fabrics.

The technology behind laser cutting allows for precise cuts with minimal material waste, making it an ideal solution for businesses that require high accuracy and efficiency in their production lines.

Advantages of Laser Cutting Machines for Manufacturing

1. Precision and Accuracy

The degree of accuracy provided by laser cutting machines is one of its main benefits in the manufacturing industry. Inconsistencies or human mistakes are frequently present in traditional cutting techniques like mechanical cutting or sawing. Laser cutting, on the other hand, uses computer-controlled systems to deliver consistent, precise cuts with tolerances as small as 0.1mm. This level of accuracy is particularly important for industries where tight specifications are critical, such as aerospace, automotive, and electronics manufacturing.

In the UAE, where precision is valued in sectors such as construction and infrastructure development, laser cutting machines can ensure that businesses produce high-quality products with minimal errors.

2. Versatility

Many materials, including non-metal materials like plastics, wood, and acrylics, as well as metals like steel and aluminum, can be cut with laser cutting machines. Because of their adaptability, manufacturers in a variety of industries can use them. Laser cutting machines are highly capable of handling tasks such as generating automotive parts, electronic components, and architectural features with ease.

Moreover, businesses in the UAE, where the market demands for custom-made products and unique designs are rising, can benefit from the ability of laser cutting machines to cut intricate patterns and designs, enabling customization and flexibility in production.

3. Cost Efficiency

A laser cutting equipment can save a lot of money over time, even though the initial cost may seem costly. Production times are accelerated, material waste is reduced, and manual labor is not as necessary with laser cutting. All of these factors contribute to lower operational costs. Additionally, the high level of automation in laser cutting means fewer resources are spent on reworking or correcting mistakes, further improving cost efficiency.

For manufacturing businesses in the UAE looking to reduce costs while maintaining or improving production quality, laser cutting machines are a smart investment. The region’s competitive manufacturing landscape demands efficiency, and laser cutting technology can help businesses remain profitable while delivering high-quality products.

4. Enhanced Rate of Production

Time is of the importance in the fast-paced manufacturing world of today. When it comes to cutting, laser cutting machines are faster than anything else. They can operate continuously because they are automated and require little human involvement, which greatly increases production output.

This is particularly advantageous for businesses in the UAE, where quick turnaround times are often essential to meet market demands. The speed of laser cutting machines not only increases productivity but also shortens the lead time between orders and delivery, allowing manufacturers to meet deadlines and keep their customers satisfied.

5. Minimized Material Waste

Laser cutting machines use advanced technology to make precise cuts without damaging the surrounding material. This has the dual benefits of being economical and environmentally benign because it produces little material waste. Reducing waste is essential for businesses that deal with pricey resources like metals to stay profitable.

In the UAE, where sustainability and environmental considerations are becoming more important, reducing material waste aligns with both business goals and governmental policies aimed at promoting eco-friendly manufacturing practices.

6. Enhanced Design Capabilities

The intricate designs that laser cutting machines can achieve are unmatched by traditional cutting methods. With the use of advanced software, manufacturers can program laser cutting machines to cut complex shapes and patterns with ease. This opens up new possibilities for creativity and innovation in product design.

Manufacturing businesses in the UAE that focus on delivering unique, customized products to their clients will find laser cutting machines particularly beneficial. Whether creating complex architectural elements or producing high-end consumer products, laser cutting offers the flexibility to execute even the most intricate designs flawlessly.

Why Laser Cutting Machines are Essential?

The UAE has established itself as a major manufacturing base on a worldwide scale, with fast-growing sectors including consumer products, automotive, aerospace, and construction. Businesses need to embrace advanced technologies like laser cutting machines if they want to stay competitive in this ever-changing market. These machines offer the accuracy, speed, and adaptability required to satisfy the growing need for premium, personalized goods.

Moreover, with the UAE’s emphasis on sustainability and resource efficiency, the reduced material waste and energy consumption of laser cutting machines offered by Rockwood Machinery make them a forward-thinking choice for manufacturers. Businesses may increase productivity and comply with the vision of a more efficient and environmentally friendly future by investing in laser cutting technology.

Laser cutting machines are now a requirement rather than a choice for manufacturing companies. Their ability to deliver precise, fast, and cost-effective solutions makes them a crucial asset for companies looking to succeed in the competitive manufacturing landscape. As the UAE continues to grow as a global manufacturing hub, investing in laser cutting technology will help businesses remain competitive, efficient, and innovative in the years to come.

Continue reading, click: Why the Latest Pug Cutting Machines Are Essential for Modern Workshops