From improving workplace safety to boosting productivity, magnetic lifters have solidified their place in the industrial sector, particularly in steel fabrication. In this article, we’ll cover why magnetic lifters in the UAE have become the go-to solution for steel fabrication and how the growing trend of industrial machinery rentals is making this technology more accessible to businesses of all sizes in the UAE.

Steel Fabrication Challenges in the UAE

The steel fabrication industry has grown exponentially over the last few decades. As major projects in construction, infrastructure, and energy demand high-quality steel structures, steel fabricators face immense pressure to deliver on time while maintaining top-notch precision and safety standards in the UAE.

One of the biggest challenges in steel fabrication is handling heavy steel plates, pipes, beams, and other components safely and efficiently. Traditional lifting methods like slings, chains, and cranes have their limitations, including the potential for accidents, damage to materials, and slower operational processes. These challenges are amplified in an environment where deadlines are tight, and any delay or mishap can have costly consequences.

Enter magnetic lifters—a modern, efficient solution that directly addresses these challenges.

The Role of Magnetic Lifters in Steel Fabrication

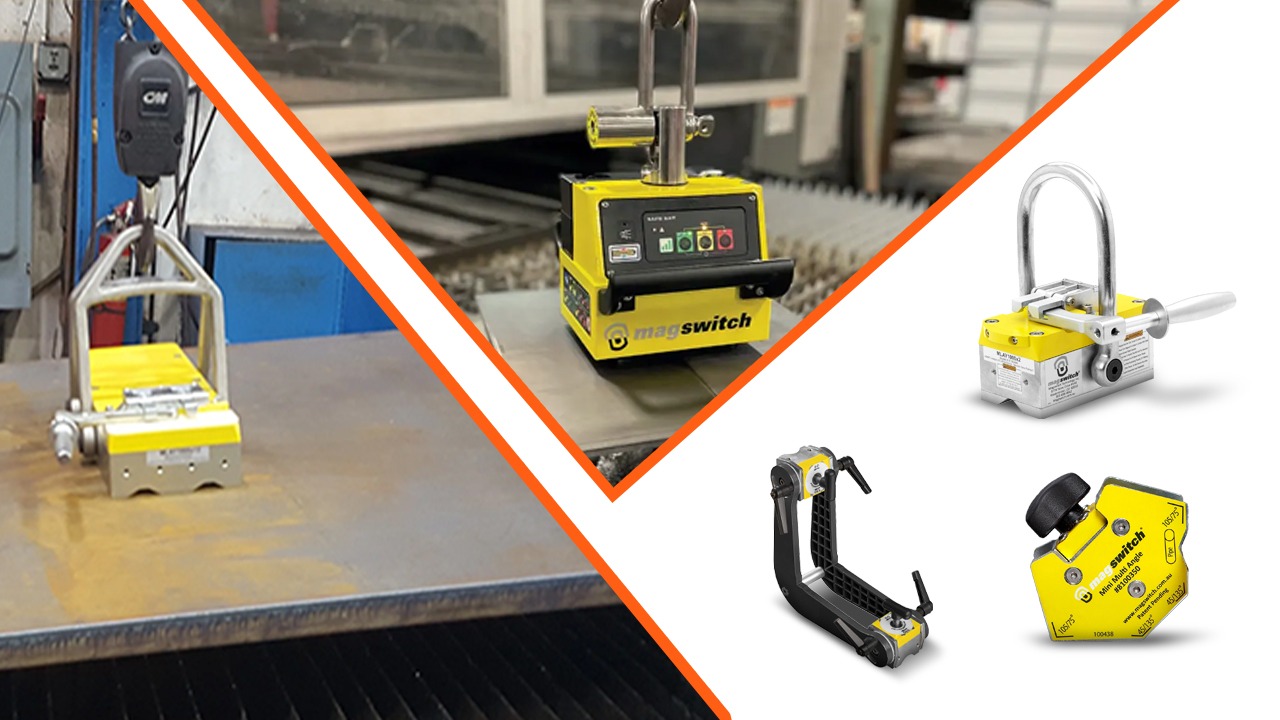

Magnetic lifters utilize powerful magnets to safely and efficiently lift and transport ferromagnetic materials like steel. These lifters come in various sizes and capacities, making them suitable for handling a wide range of steel components used in fabrication processes. Whether you’re lifting large steel sheets or moving smaller components, magnetic lifters in the UAE provide the versatility needed to streamline operations.

Here’s why magnetic lifters are ideal for steel fabrication:

1. Enhanced Safety

Safety is a top priority in any industrial environment, and steel fabrication is no exception. The use of slings or chains to lift steel components can often lead to accidents, especially when loads are not properly balanced or secured. Magnetic lifters, on the other hand, significantly reduce the risk of accidents.

Because they rely on magnetic force to hold materials securely, the chances of a steel component slipping or dropping during lifting are minimized. Additionally, magnetic lifters eliminate the need for workers to handle materials manually, reducing the likelihood of injuries caused by strain or mishandling.

2. Improved Efficiency

One of the key benefits of using magnetic lifters in steel fabrication is the speed at which materials can be moved and positioned. One worker can use magnetic lifters with little effort, in contrast to traditional lifting techniques that may call for several workers to secure and balance loads. This leads to faster loading, unloading, and positioning of steel components, allowing fabricators to meet tight deadlines more easily.

Moreover, magnetic lifters are easy to operate, meaning less training or setup downtime. This is particularly helpful in high-stress fabrication settings where every second matters.

3. Protecting Steel Components from Damage

In steel fabrication, maintaining the integrity of materials is crucial. Steel components that are scratched, bent, or damaged during the lifting process can lead to production delays and increased costs. Traditional lifting methods, such as using hooks or chains, can cause surface damage to steel products, especially if they are not handled carefully.

Magnetic lifters, however, hold steel components securely without causing surface damage. The magnets reduce the possibility of dents, scratches, and other flaws by giving the material’s surface an equal hold. This improves the overall accuracy of the fabrication process while also maintaining the steel’s quality.

4. Versatility Across Different Applications

Steel fabrication involves handling various types of steel products, from large sheets to pipes and beams. Their adaptability is one of the main benefits of magnetic lifters. They can be used to lift a wide range of steel components, regardless of their size or shape, making them an ideal solution for complex fabrication processes.

In the UAE, where steel fabrication is often tied to massive construction and infrastructure projects, the ability to adapt to different materials and tasks is crucial. Magnetic lifters provide the flexibility needed to handle diverse project requirements, helping fabricators stay competitive in a demanding market.

5. Cost-effective solutions with Industrial Machinery Rentals

While the benefits of magnetic lifters are clear, many businesses—particularly smaller steel fabrication companies—may be hesitant to invest in expensive machinery. Fortunately, the trend of renting out industrial machinery is facilitating simpler access to the latest technologies for enterprises without requiring large upfront investments.

Renting magnetic lifters allows companies to use state-of-the-art equipment when they need it, without the long-term commitment of purchasing and maintaining expensive machinery. This is particularly beneficial for companies that use magnetic lifters only occasionally or for specialized tasks. By opting for rentals, companies can maintain flexibility in their operations and better manage their budgets.

Conclusion: A Smart Investment for the Future

For steel fabricators in the UAE, magnetic lifters offer all these benefits and more. By providing a safer, faster, and more efficient way to handle steel components, magnetic lifters have become an indispensable asset in the industry. Moreover, with the rise of industrial machinery rentals in the UAE, businesses can now access these cutting-edge tools without the financial strain of large capital investments. This makes magnetic lifters an ideal solution for companies looking to enhance their steel fabrication capabilities while remaining cost-efficient.

As the demand for high-quality steel fabrication continues to grow in the UAE, adopting magnetic lifter technology will help businesses stay competitive, deliver projects on time, and ensure the safety of their workforce. Rockwood Welding Automation offers the best Magnetic Lifters in the GCC at the best price and exceptional service. Contact us today and get connected with our experienced sales team to learn more.

To read more click: Top 5 Essential Cutting Machines You Need to Know in the UAE