Hydraulic Shear Machines

- Home / Products / Cutting & Drilling / Hydraulic Shear Machines

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

Hydraulic Shear Machines in UAE

Hydraulic shear machines represent cutting-edge solutions in metal fabrication, offering precision and efficiency in sheet metal processing. These machines leverage hydraulic power to shear through various materials with remarkable accuracy. Employing advanced technology, hydraulic shear machines in UAE feature redundant safety measures, including 24VDC safety valves with optics and pressure indication, ensuring a secure operational environment. Equipped with electronic compensation for hydraulic oil temperature, these machines optimize performance across a range of working conditions. Their front arms, sliding on linear recirculating ball screw guides, provide an exceptional grip on sheet metal, enhancing the overall cutting precision. Incorporating electronic safety controls on side doors, high-frequency laser sensor systems, and software-configured electronic muting systems, hydraulic shear machines in UAE are at the forefront of safety and innovation in the metalworking industry. With connectivity options such as Ethernet, USB, and VGA, these machines are not only powerful but also adaptable for seamless updates, backups, and peripheral integrations.

Hydraulic Shear Machine C3006 CNC

Features

compact CNC control. Max. cutting length: 3055mm Max. thickness: 6 mm.

stabilized, welded steel that allows to stand big efforts without deformation.

The life of the blades is 4 times higher than other shearing systems.

Specifications

- A mechanized block bench featuring integrated spheres for smooth sheet movement is equipped with several essential features:

- The initial support is machined to a square of 1000mm with a millimeter scale.

- It includes three 1000mm millimetered stand arms.

- LASER lighting is employed along the cutting line, complemented by LED front lighting.

- The front is fitted with polycarbonate protection screens that provide a clear view of the cutting line.

- It ensures distortion-free cutting of narrow strips.

- The upper and lower blades are four-cutting edged, with a durable 90º angle suitable for steel cutting.

- Operation is facilitated by a safety pedal and an emergency stop mechanism.

- The back has an opening with safety optoelectronic devices.

- The machine operates at a low noise level, enhancing the operator’s work quality.

- A material extraction ramp at the lower cutting zone allows the material to smoothly slide down for extraction.

- The cutting length is 3055mm.

- It has a cutting capacity of 6 mm in steel (450N/mm2) and 4 mm in stainless steel (700N/mm2).

- The gauge displacement is 700 mm.

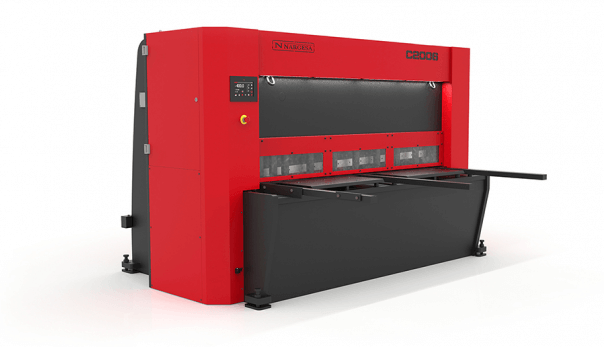

Hydraulic Shear Machine C2006 CNC

Features

compact CNC control.

Max. cutting length: 2030 mm Max. thickness: 6 mm. Thickness in Stainless Steel: 4 mm.

Specifications

The machine features two stand arms each measuring 1000mm, equipped with LASER lighting along the cutting line and LED front lighting. To ensure visibility, it includes front polycarbonate protection screens. Its design allows for the distortion-free cutting of narrow strips. The upper and lower blades, each with four cutting edges at a 90º angle, are durable and suitable for cutting steel. Operation is facilitated by a safety pedal and emergency stop, while safety optoelectronic devices are present in the back opening. The machine operates at a low noise level, enhancing the operator’s working environment. Material extraction is facilitated by a ramp located in the lower cutting zone. The specifications include a cutting length of 2030mm, a cutting capacity of 6mm in steel (450N/mm2) and 4mm in stainless steel (700N/mm2). The gauge displacement is 700mm, and it features a goose neck for longer cuts with a length of 190mm. The machine operates at a rate of 10 strokes per minute across its entire length.