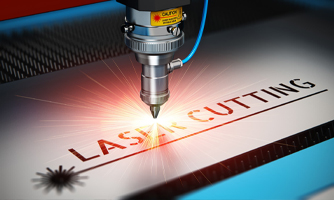

The field of metalworking has undergone a revolution with the introduction of laser technology. Metal laser cutting, in particular, has become a cornerstone of modern manufacturing and fabrication processes. In this blog, we’ll dive into the world of metal laser cutting, examining the various types of laser cutting methods used in metals and how to choose the right laser cutting machine for your needs.

Metal Laser Cutting: A Brief Overview

Metal laser cutting is a precise and versatile process that uses a highly focused laser beam to cut, engrave, or mark metal surfaces. It has gained immense popularity in various industries due to its ability to deliver intricate and accurate cuts. The choice of laser cutting method is primarily determined by the type of metal being processed and the specific application.

1. CO2 Laser Cutting

CO2 laser cutting is one of the most widely used methods for cutting metals. It operates by emitting a carbon dioxide laser beam to melt, burn, or vaporize the material. The energy from the laser source is precisely controlled to create clean and sharp cuts on a wide range of metals.

2. Fiber Laser Cutting

Fiber laser cutting is another popular technique used for metals. It employs a high-power fiber laser source to cut through metals with outstanding precision and speed. This method is particularly well-suited for cutting thin and reflective materials.

3. YAG Laser Cutting

YAG (Yttrium Aluminum Garnet) laser cutting is commonly used for fine and intricate cutting applications, especially in jewelry and electronics industries. This method utilizes a solid-state crystal medium and is known for its high beam quality.

How To Choose The Right Laser Cutting Machine?

The world of manufacturing and fabrication has seen a remarkable transformation with the introduction of laser cutting machines. These versatile tools offer unmatched precision and efficiency, making them an essential asset for businesses worldwide. When it comes to selecting the right laser cutting machine, several factors come into play. In this comprehensive buying guide, we’ll explore the key considerations, with a special focus on laser marking machines in the UAE, laser cleaning & rust removal machines, and the advanced laser features offered by Rockwood.

Understanding Your Needs

Choosing the right laser cutting machine starts with a clear understanding of your specific needs and requirements. Here are some essential questions to ask:

Materials: What type of materials will you be working with? Different machines are designed for metals, plastics, or organic materials.

Thickness: What is the thickness of the materials you plan to cut or mark? The machine’s power and capabilities should align with your material thickness.

Application: Are you primarily cutting, marking, or engraving? Different laser machines are optimized for specific applications.

How To Choose The Right Laser Cutting Machine? A Buyer’s Guide

In today’s rapidly evolving world of manufacturing and fabrication, laser cutting machines have become indispensable tools for precise and efficient metal processing. Whether you’re in the United Arab Emirates (UAE) or anywhere else in the world, selecting the right laser cutting machine can significantly impact your production quality and efficiency. In this comprehensive guide, we will walk you through the key factors to consider when choosing a laser cutting machine, with a special focus on laser marking machines in the UAE and laser cleaning & rust removal machines.

The first step in choosing the right laser cutting machine is to understand your specific needs and requirements. Ask yourself:

- What materials will you be working with? Different machines are designed for various materials, including metals, plastics, or organic materials.

- What is the thickness of the material? The machine’s power and capabilities must match the thickness of the materials you’ll be working with.

- What type of cutting or marking will you be doing? Some machines are more suitable for cutting, while others excel at engraving or marking.

Precision and Marking Quality

If you’re in the UAE and need a laser marking machine, precision and marking quality are paramount. Look for a machine that can deliver high-resolution marks, such as serial numbers, barcodes, logos, or intricate designs, with exceptional accuracy.

Ease of Use

Consider the user-friendliness of the machine, especially if you have operators who might not be highly experienced. A machine with an intuitive interface and easy setup can save time and reduce the learning curve.

Maintenance and Durability

Ensure that the machine is designed for easy maintenance and can withstand the environmental conditions in the UAE. Dust and heat can impact the longevity of your equipment.

Laser Cleaning & Rust Removal Machines in UAE

Cleaning Efficiency

For laser cleaning and rust removal in the UAE, efficiency is critical. Look for a machine that can effectively remove rust, paint, and contaminants from metal surfaces. High-energy laser beams and precise control are essential for a thorough cleaning process.

Safety Features

Laser cleaning machines should have robust safety features to protect operators and bystanders. Check for features like automatic shut-off in case of anomalies or unauthorized access.

Versatility

Consider the versatility of the machine. Can it handle various metal types and surface conditions? A versatile machine is an asset in dynamic manufacturing environments.

Rockwood has solidified its reputation as a provider of top-tier laser cutting machines and advanced laser features in the UAE. When you’re in the market for a laser cutting machine, Rockwood’s offerings are certainly worth exploring due to their commitment to quality and innovation.

In conclusion, choosing the right laser cutting machine is a pivotal decision that can greatly impact your business’s success. By thoroughly understanding your needs, evaluating the machine’s capabilities, setting a budget, and considering the manufacturer’s reputation, you can make a well-informed choice. With Rockwood’s advanced laser features and quality machines, you can further enhance your precision and efficiency, solidifying it as a dependable partner for your laser cutting requirements.

Find out more about Save money with versatile pipe cutting machine manufacturers in UAE