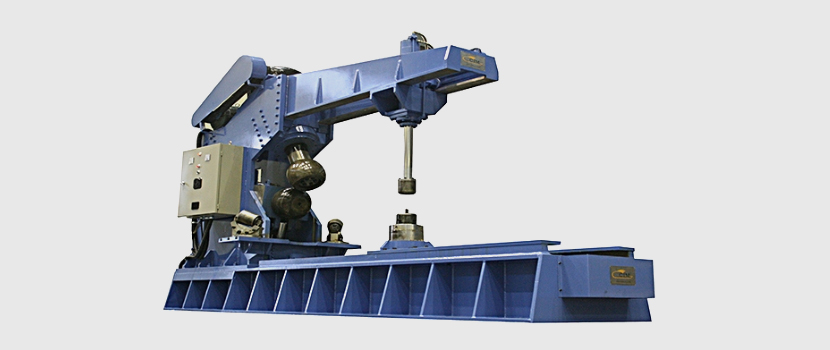

Flanging Machine

- Home / Products / Bending & Forming / Flanging Machine

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

HSM Flanging Machines in UAE

Feature

– Use for making vessel mainly

– Knuckle working: FD, SD, ED, AD, DD

– Oil cooling system maintain regular temperature

– Fixing center of vessel <hole, welding JIG>

– All operate Hydraulic pressure and

drive exact working strong power

– Lever Control Unit

– Sol-valve Control Unit

– Operate with NC control, knuckle is smooth

– Total 9~13 of mold

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Vessel Beveling Device

– Vessel insert / outlet unit

– Auto Lubrication

– Dies for Working (walkway)

– Small working JIG (Ø300~Ø1,000)

– Mold change unit

– Additional mold excluding standard

– Dust cover for machine

– Digital System

– NC Control system

– Electronic sol valve control unit

Model No: CIM FM

| min | max | |

| Thickness | 6mm | 80mm |

| Flange Diameter | 350mmm | 8,000mm |

| Knuckle Radius | 10mm | 1,500mm |