Hydraulic Presses And Manipulator

- Home / Products / Bending & Forming / Hydraulic Presses And Manipulator

Download our complete Company Profile

GET A QUOTE

OVERVIEW

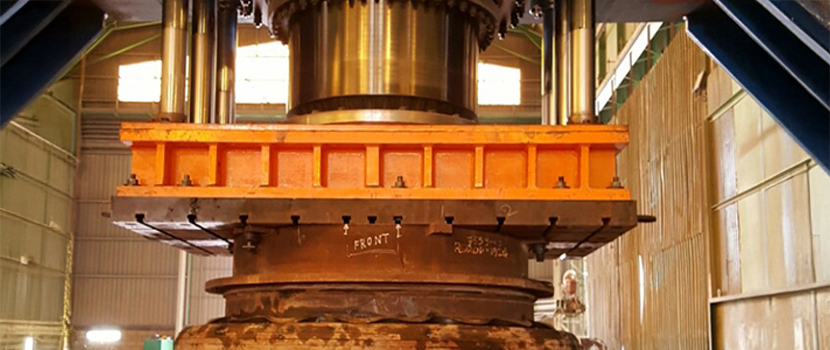

Hydraulic Presses and Manipulator in UAE

Hydraulic presses and manipulator machines are essential tools for various industrial applications. Hydraulic presses utilize high-pressure fluid to generate force, ideal for metal forming, stamping, and shaping materials with precision and power. Manipulators, on the other hand, enhance ergonomics and efficiency by allowing operators to control heavy objects with ease. These machines are commonly used in manufacturing, assembly, and material handling, offering reliable, robust solutions for increasing productivity and ensuring worker safety in challenging environments.

Feature

– Work at high speed.Oil cooling system prevent oil temperature rising

– It has the function of quick workability by selecting the up/down position.

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Auto Lubrication

– NC control system

– Forming Mold, JIG

– Forming Bottom Mold Feeding Hydraulic device

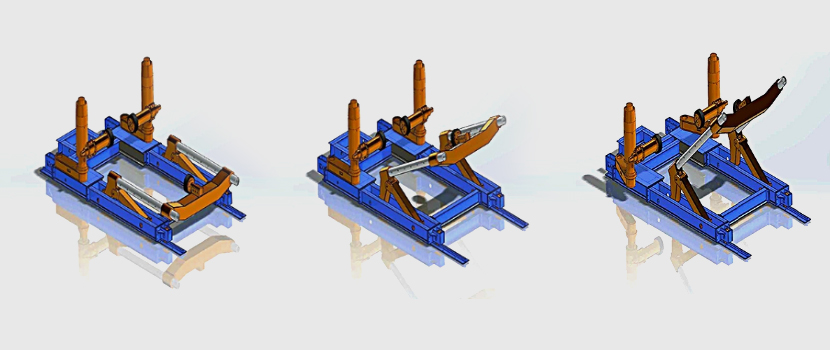

– Manipulator Small Devise ∅400∼∅1000

Model No: CIM PMP

| min | max | |

| Press Capa | 3ton | 50ton |

| Working Diameter | ∅400mm | ∅9,000mm |

Feature

– Decrease loss of edge bending

– Shorten operating time and decrease material loss

If rolling after edge bending in hydraulic press

– Oil cooling system prevent oil temperature rising

– Adjust Up / Down speed

– Guarantee Term: 24 months

– Fast speed A/S reaction

– Up speed : 90 ~ 180 mm/sec

– Down speed : 80 ~ 150 mm/sec

– Press speed : 3 ~ 14 mm/sec

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– In / Out conveyor roller

– Wireless Remote Control

– Bending Mold, JIG

– Bending Bottom Mold Feeding Hydraulic device

– Bending Hoist

Model No: BR4

| min | max | |

| Press Capa | 100ton | 20,000ton |

| Ram stroke | 300mm | 3,000mm |

| Open Height | 1,000mm | 6,000mm |

| Inside Width | 700mm | 9,000mm |

Feature

– Decrease loss of forming

– Shorten operating time and decrease material loss if forming after edge forming in hydraulic press

– Oil cooling system prevent oil temperature rising

– Adjust Up / Down speed

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– In/Out conveyor roller

– Wireless Remote Control

– Forming Mold, JIG

– Forming Bottom Mold Feeding Hydraulic device

– Vessel Hoist

Ball Tank – VESSEL

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– In/Out conveyor roller

– Wireless Remote Control

– Forming Mold, JIG

– Forming Bottom Mold Feeding Hydraulic device

– Forming Hoist

– Vessel Hoist

– Vessel Automatic Manipulator

– Up / Down Hi speed

Model No: CIM HP

| min | max | |

| Press Capa | 100ton | 20,000ton |

| Ram stroke | 300mm | 3,000mm |

| Open Height | 1,000mm | 5,000mm |

| Inside Width | 700mm | 9,000mm |

Feature

– Use mainly for shipbuilding and sea port

– Easy working Automatic system

– Oil cooling system prevent oil temperature rising

– Adjust Up / Down speed

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– In / Out conveyor roller

– Wireless Remote Control

– Bending Mold, JIG

– Bending Bottom Mold Feeding Hydraulic device

– Hoist

– Up / Down Hi speed

Model No: CIM PHP

| min | max | |

| Press Capa | 100ton | 5,000ton |

| Ram stroke | 300mm | 3,000mm |

| Open Height | 1,000mm | 5,000mm |

| If bigger than above, produce by order. | ||

Feature

– Shorten operating time and decrease material loss if Hot Forming after Forming in hydraulic press

– When over than 35t, No need Die Cushion

– Cold forming MAX is 16T-01600mm.

– Oil cooling system prevent oil temperature rising

– Adjust Up / Down speed

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– In/Out conveyor roller

– Wireless Remote Control

– Up / Down Hi speed

– Die Cushion

Model No: CIM HPHOT

| min | max | |

| Press Capa | 100ton | 20,000ton |

| Ram stroke | 300mm | 3,000mm |

| Open Height | 1,000mm | 4,000mm |

| Inside Width | 1,000mm | 7,000mm |

Feature

– Decrease loss of edge bending

– Shorten operating time and decrease material loss if rolling after edge bending in hydraulic press

– Oil cooling system prevent oil temperature rising

– Adjust Up / Down speed

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– In/Out conveyor roller

– Wireless Remote Control

– Up / Down Hi speed

Model No: CIM HPC

| min | max | |

| Press Capa | 100ton | 3,000tonn |

| Ram stroke | 300mm | 3,000mm |

| Open Height | 1,000mm | 3,000mm |

| Inside Width | 700mm | 4,000mm |

Feature

– Make the deep vessel, container and bottle

– Type: frame / 4 post

– High Accuracy

– High productivity and speed.

– Oil cooling system prevent oil temperature rising

– Adjust Up / Down speed

– Guarantee Term: 24 months

– Fast speed A/S reaction

Option

– Auto Lubrication

– Digital scale

– Hot Press

– Electronic balancing system (main cylinder 2 more)

– NC control system

– Up / Down Hi speed

– Touch screen

– LVDT system

– In/Out working dies

– In / Out conveyor

– Cushion Device

– Photo-electric Safety Device

– Prssing Speed 7mm/sec ~ Up

Model No: CIM HPDD

| min | max | |

| Press Capa | 100ton | 10,000tonn |

| Ram stroke | 300mm | 3,000mm |

| Open Height | 1,000mm | 3,000mm |

| Inside Width | 700mm | 6,000mm |