Magnetic Lifters And Welding Fixtures

- Home / Products / Material Handling / Magnetic Lifters And Welding Fixtures

MATERIAL HANDLING

BROCHURES

Download our complete Company Profile

GET A QUOTE

OVERVIEW

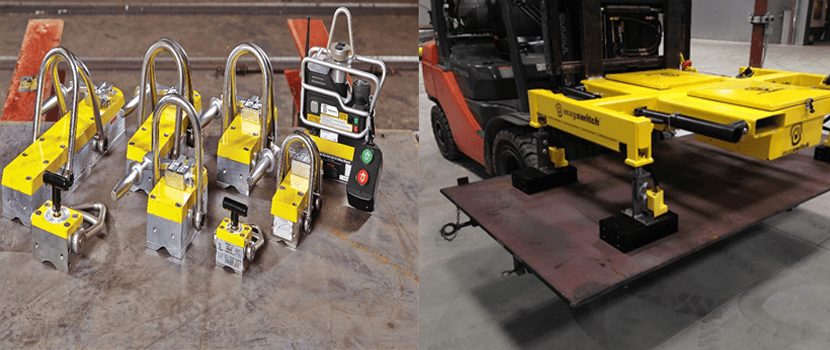

Magnetic Lifters in UAE – STRONGER, EASIER AND SAFER TO USE

Safety is paramount when using magnetic lifters. At Rockwood, our priority is just that—introducing tools that improve the overall safety and efficiency of all types of work environments and metal handling applications. When considering the substantial convenience of choosing a magnetic lifter over hooks and slings, it’s easy to see how much they can improve efficiency in steel handling. Magnetic Lifters in UAE for Magnetic Clamping, Magnetic Welding Angles, as Mag Pry for aligning steel plates before welding, Magnetic Sweeper etc.

We offer magnetic lifters and welding fixtures from Magswitch with substantial advantages in strength, size, control and features over old technology. This translates into safer lifting for your team. Permanent magnets are now employed to lift heavy steel where only hooks or straps were previously trusted. The advancements employed by Magswitch technology take magnetic lifting capabilities to a whole new level of safety and strength.

Unlike older technologies, our magnetic lifters exert full hold force on thinner steel.

- The majority of steel lifted is less than 1inch thick.

- Better hold on uneven, dirty steel or round shapes.

- Magswitch lifters feature a more concentrated flux,

- Resulting in a safer hold when lifting these types of materials.

- Easier to activate on thin material than old technology lifters.

- Magswitch lifters are easier to turn on.

- Especially beneficial in larger lifters, where older technology makes working with thin steel (1 inch or less) very difficult.

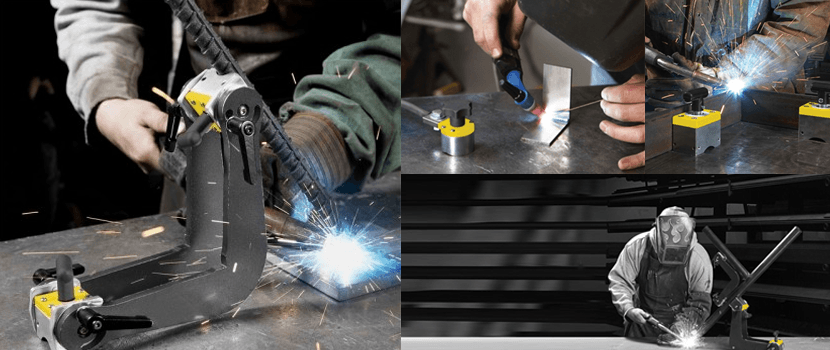

WELDING & FABRICATION

As magswitch becomes more of a mainstream product, professional welders and fabricators are demanding more tools and sending in ideas that expand on the tremendous application benefits already taking place worldwide. unprecedented and timesaving characteristics like a self-cleaning surface and powerful hold on thin material are quickly becoming a favorite among casual welders, too. consider the following game-changing impacts of magswitch on welding and fabrication:

- Large sheet leveling in seconds.

- True sheet de-stack without any sticking.

- Lightweight magnets that reliably and safely

- Hold heavy loads .

- Holding power that doesn’t rely on electricity

- To stay activated.

- Cordless heavy lifting for hard-to-reach steel