Choosing suitable lifting equipment is key to material handling an efficient, safe, and economical operation. Such a comparison is made in this paper to highlight the main differences, advantages, and disadvantages of two opposing types of equipment. The place of application will be the UAE; it is undergoing a gubernatorial sea change with modern-day industrial solutions like magnetic lifters and technologically sophisticated machineries such as laser-cutting machines reinventing industry.

What Are Magnetic Lifters?

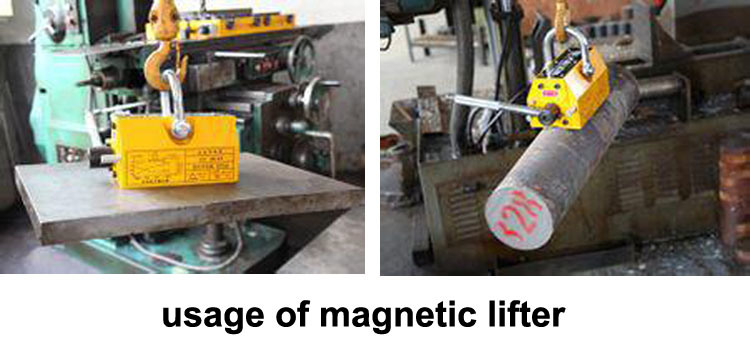

Magnetic lifters in UAE are advanced lifting devices using very powerful magnets to lift and carry ferrous materials like steel plates, bars, or rods. They can be applied manually, battery, or electromagnetic. Their tough design is well—suited for heavyweight tasks in industries of steel fabrication, warehousing, and construction.

What Is Traditional Lifting Equipment?

Traditional lifting equipment includes chains, slings, hooks, cranes, and forklifts. These tools use mechanical, hydraulic, or pneumatic systems to lift and transport materials. Such equipment is versatile; however, additional attachments and manual adjustments are required to accomplish a specific task.

Key Factors for Comparison

A comparative study is provided for magnetic lifters against traditional lifting equipment on numerous parameters:

1. Efficiency

Magnetic lifters are extremely efficient and provide the desired speed and ease while lifting ferrous materials. No additional clamps, slings, or chains are needed to hold objects. They easily lift the load and let it down with minimal effort by an operator, thereby greatly reducing downtime. Comparatively, traditional lifting equipment will take the extra—time of setting up, and attaching slings/chains, all adding scrupulous time for completion, especially in high-volume situations.

2. Safety

Safety is the most important part of any working environment. In this respect, magnetic lifters are more capable, as their design encapsulates materials and completely prevents slipping. Some of them are fitted with fail-safe mechanisms, so should the power be cut off, the magnet will hold the load. Conversely, if not properly maintained or operated, traditional lifting equipment can also be unsafe. Wear/tear in slings and chains can increase accidents.

3. Versatility

While magnetic lifters are incredibly effective in lifting ferrous materials, they are limited in application to handling non-ferrous materials like aluminum or copper. Traditional lifting equipment comes into play here, as it can work on a wider range of materials with the right attachments.

4. Maintenance

Magnetic lifters are generally very low on maintenance as compared to traditional lifting equipment, being fewer with mechanical components. Permanent magnetic lifters are the most dependable and economical because they have no electrical parts or moving components.

In contrast, traditional lifting equipment needs a regular check and maintenance of the integrity of chains, hooks, and hydraulic systems. Though more expensive to acquire initially, magnetic lifters often provide greater long-term value due to the substantially reduced costs for maintenance and their operational effectiveness.

5. Cost-Effectiveness

The same also means less expense for the user with the fact that magnetic lifters do not require consumables such as slings and chains. Traditional lifting equipment tends to be less expensive at outset but ultimately entails greater continuing costs from frequent maintenance, replacement parts, and longer times for setup.

6. Environmental Impact

Magnetic lifters are environmentally friendly since they do not require any fuel and do not emit harmful gases. Using permanent magnetic lifters, an electric-free kind, has particular appeal for green enterprises in the UAE. Diesel or gas-fueled traditional lifting equipment tends to be polluting and requires more energy to operate; hence, they are less eco-friendly.

Applications in the UAE

The industrial sector in the Emirates is witnessing rapid development, with more emphasis laid on advanced machinery and technology. Magnetic lifters are becoming a viable option for companies in the steel fabrication and warehousing industry, owing to their efficiency and reliability. This particular type of block is very useful for the transportation of materials used in laser cutting machines in UAE, as precision and safety are very crucial.

Meanwhile, traditional lifting gear provides solutions, complements, and considerable value for a range of materials and applications within industries such as construction and logistics. Many companies in the UAE are going hybrid, deploying magnetic lifters and conventional technology.

Choosing the Right Solution

The choice between magnetic lifters and traditional lifting equipment will depend on several factors, such as the type of material to be manipulated, operational considerations, and budget. Here are the points to guide you:

- For Steel Fabrication: Magnetic lifters are the ideal choice for handling steel plates, sheets, and rods, especially when used alongside laser cutting machines to streamline workflows.

- For Diverse Material Handling: Traditional lifting equipment is better suited for operations involving various materials, including non-ferrous metals and irregularly shaped loads.

- For High-Volume Operations: Magnetic lifters offer faster and more efficient handling, making them suitable for high-volume environments like manufacturing plants.

- For Temporary or Flexible Needs: Traditional lifting equipment may be more practical for temporary projects or applications requiring frequent adjustments.

Conclusion

On each side of this issue stands a unique aspect plus limitations in magnetic lifters and traditional equipment. Magnetic lifters provide greater efficiency, safety, and less maintenance, while traditional lifting technology gives one the possibility of a wider operation spectrum. With their specific needs in mind, businesses in UAE can save on their operational costs by choosing the right kind of lifting solution.

To provide a competitive advantage in the steel fabrication and laser cutting segments, magnetic lifters would complement advanced laser cutting machines from Rockwood Machinery. With this combination, the industries should be in a better position to increase sustainability, safety, and productivity in their operations.