In today’s continuously changing industrial scene, precision, efficiency, and innovation are essential to success. Among the most transformative technologies reshaping the manufacturing and fabrication sectors is laser cutting. If you’re still relying on traditional cutting methods like plasma cutting or hydraulic shearing, it’s time to explore the benefits of laser cutting machines in UAE. At the same time, combining laser cutting machine with reliable hydraulic shear machines offers a comprehensive fabrication solution, boosting productivity and precision.

What are Laser Cutting Machines?

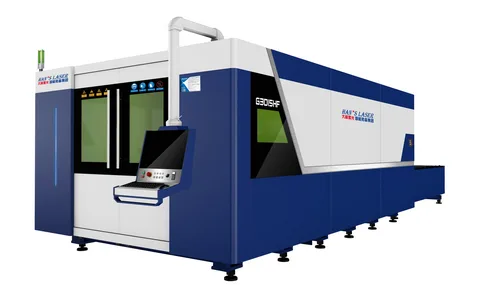

Laser cutting machines use a concentrated laser beam to cut through materials with extreme precision. Laser cutting generates crisp edges without requiring substantial finishing by melting, burning, or vaporizing material. These machines are commonly used for cutting metals such as stainless steel, aluminum, and carbon steel, as well as nonmetallic materials like as plastics, wood, and acrylic.

Laser cutting is extremely common in industries such as automotive, aerospace, construction, and metal production due to its speed, accuracy, and versatility.

How Do Laser Cutting Machines Work?

Laser cutting machines operate through a controlled process:

- Laser Beam Generation: High-powered laser beams are often generated using CO₂, fiber optics, or solid-state lasers.

- Focusing the beam: The laser beam is directed and focussed onto the workpiece using a lens or mirror.

- Material Interaction: The laser heats the material, vaporizing or melting it. Assist gases like oxygen or nitrogen may be used to enhance the process.

- Controlled Cutting: CNC (Computer Numerical Control) systems guide the laser head, ensuring precise and intricate cuts.

This controlled approach delivers high precision with minimal material waste, making it superior to traditional cutting techniques.

Why Switch to Laser Cutting Machines?

Here are the key reasons why laser cutting machines in UAE are revolutionizing the manufacturing industry and why your business should make the switch:

1. Unmatched Precision and Accuracy

Laser cutting machines deliver high-precision results, achieving tolerances as tight as +/- 0.1 mm. Whether you’re working on delicate designs or large-scale projects, laser cutting produces clean, smooth edges with no burrs.

Traditional methods like hydraulic shear machines, while effective for straight cuts, cannot achieve the same level of detail as laser cutting. Businesses that integrate laser cutting machines can easily manage complex and specialized designs.

2. Versatility Across Materials

Laser cutting machines are versatile and can cut a variety of materials, including:

- Metals: Stainless steel, mild steel, aluminium, brass, and titanium.

- Non-metals: Acrylic, wood, plastics, rubber, and textiles.

This adaptability enables manufacturers to expand their manufacturing capacities without requiring extra tools.

3. Enhanced Speed and Efficiency

Laser cutting machines may operate at higher speeds while maintaining precision, as opposed to traditional cutting processes. They can handle large production volumes efficiently, reducing downtime and increasing output.

When combined with Hydraulic Shear Machines for bulk material processing, laser cutting machines ensure streamlined workflows and maximum productivity.

4. Minimal Material Waste

Laser cutting is an extremely efficient procedure that reduces material waste. The focused beam cuts with minimal kerf width, ensuring optimal material utilization. This not only lowers prices, but also promotes sustainable manufacturing techniques.

5. Low Maintenance and Operating Costs

Modern fiber laser cutting devices require less maintenance than plasma or mechanical cutting instruments. There are fewer moving components and no direct contact with the cloth, thus wear and tear is low.

6. Improved Safety Standards

Laser cutting machines are generally automated and enclosed, which reduces the risk of accidents in the workplace. Features like automatic shut-off, safety sensors, and minimal manual intervention make them a safer alternative to traditional cutting tools.

Applications of Laser Cutting Machines

Laser cutting machines are widely used across industries, including:

- Metal Fabrication: Cutting of metal sheets, pipes, and profiles for use in construction, automotive, and industrial applications.

- Aerospace: Accurate cutting of parts that adhere to strict industrial requirements.

- Signage and Advertising: Creating custom designs, logos, and patterns on acrylic, wood, and metal.

- Automotive: Producing accurate parts, brackets, and panels for vehicles.

- Architecture: Fabricating decorative elements, facades, and intricate metal designs.

For businesses in the UAE, investing in laser cutting machine ensure a competitive edge in these fast-growing industries.

Why Choose Rockwood Machinery?

At Rockwood Machinery, we are committed to providing state-of-the-art industrial solutions, including laser cutting machines and hydraulic shear machines. Here’s why we are the trusted choice:

- Premium Products: We offer a wide range of cutting machines equipped with the latest technology.

- Professional Assistance: To guarantee smooth functioning, our staff offers installation, instruction, and post-purchase assistance.

- Local Presence: With a strong presence, we provide fast and reliable service to meet your production needs.

- Comprehensive Solutions: From precision laser cutting to heavy-duty shear machines, we deliver tools to enhance your operations.

Disadvantages of Traditional Cutting Methods

Even though conventional techniques like hydraulic shear machines have been in use for many years, they have several drawbacks:

- Limited Precision: Hydraulic shear machines often produce less precise cuts, especially for intricate designs.

- Material Waste: These machines can generate significant material waste due to the need for additional cutting and finishing processes.

- Tool Wear and Maintenance: Hydraulic shear machines require regular maintenance and tool replacement, increasing operational costs.

Conclusion

Switching to laser cutting machines is a smart investment for businesses seeking precision, speed, and versatility. When paired with hydraulic shear machines, manufacturers can achieve a fully optimized workflow for bulk processing and detailed fabrication.

At Rockwood Machinery, we offer premium industrial solutions to meet your cutting needs. Whether you are looking for an advanced laser cutting machine or a reliable hydraulic shear machine, we’ve got you covered.

Get in touch with us right now to find out how Rockwood Machinery can improve your production capacity and advance your company.

To read more, click: Exploring The World Of Welded Studs in UAE: Types And Uses