From crafting intricate metal designs to achieving perfect cuts on heavy-duty materials, fabrication demands machinery that not only meets high standards but also optimizes workflows. Among the essential equipment in this industry, pug cutting machines stand out as an indispensable asset for metal fabrication businesses. A pug cutting machine may greatly increase production and produce precise results in any size of the manufacturing facility, from a small workshop to a large one. Let’s delve into why pug cutting machines are a must-have for every fabrication industry in the UAE, and explore how these machines can work in synergy with other advanced tools like laser marking machines in the UAE.

What are Pug Cutting Machines?

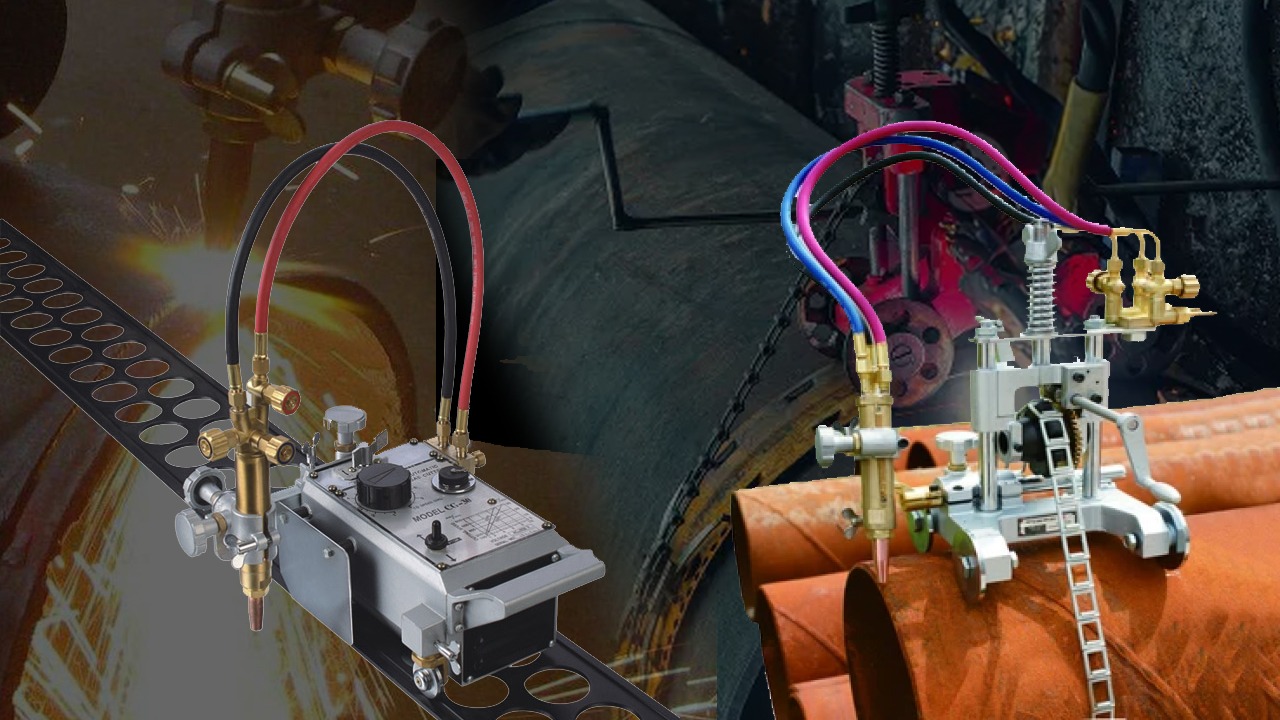

Pug Cutting Machines in UAE are advanced CNC cutting machines that utilize a variety of cutting tools, including laser, plasma, and water jet, to precisely cut through a wide range of materials. From sheet metal to thick steel plates, these machines can handle diverse cutting tasks with ease and accuracy.

Why are Pug Cutting Machines Essential for the Fab Industry?

- Improved Precision and Accuracy:

- Laser Cutting Machines: These devices create clean, burr-free cuts by using a powerful laser beam to cut materials with remarkable accuracy.

- Plasma Cutting Machines: Using a high-temperature plasma arc to effectively cut metal sheets, plasma cutting machines are perfect for cutting thicker materials.

- Water Jet Cutting Machines: Offering versatility and flexibility, water jet cutting machines can cut through almost any material, including delicate fabrics and hard composites.

- Enhanced Productivity and Efficiency:

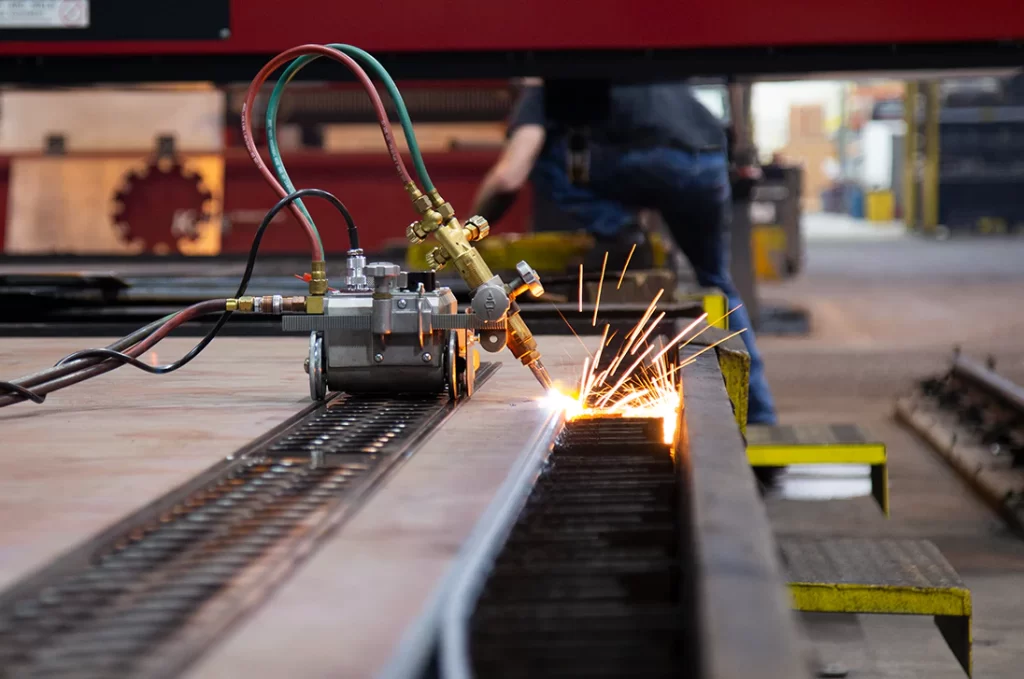

- Automated Operations: Pug cutting machines have a high degree of automation, which lowers the amount of manual labor and boosts output.

- Reduced Downtime: Advanced features like automatic tool change and material handling systems minimize downtime, ensuring continuous operation.

- Outstanding Quality and Finish:

- Clean Cuts: These machines’ accurate cutting capabilities produce smooth, clean edges, doing away with the need for further finishing procedures.

- Consistent Quality: Automated operations and precise control over cutting parameters ensure consistent product quality.

- Adaptability and Versatility:

- Diverse Material Cutting: Pug cutting machines can cut metals, polymers, wood, and composites.

- Customizable Cutting Patterns: Advanced CNC programming allows for the creation of intricate and complex cutting patterns.

Key Features of Pug Cutting Machines

Pug cutting machines are not just popular for their utility but also for the features that make them user-friendly and efficient:

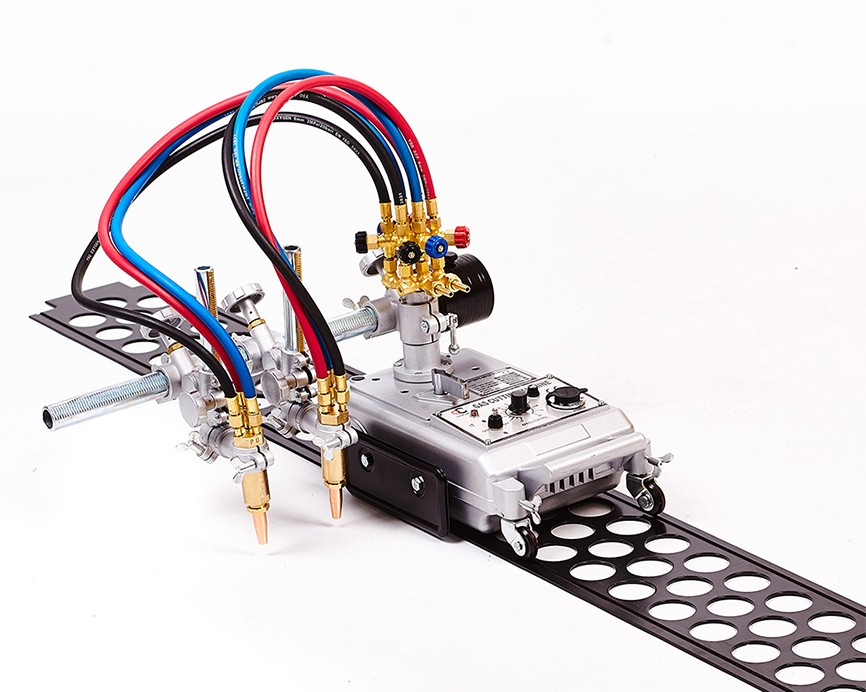

- Adjustable Cutting Speed: Operators can control the cutting speed based on the material thickness, making it easier to achieve smooth, precise cuts with minimal operator effort.

- Bevel and Straight Cuts: Pug cutting machines can be adjusted to cut bevels, which is particularly useful for preparing edges for welding. Straight-line cutting capabilities enable rapid, consistent cuts on metal sheets.

- Portable Design: These machines are compact and portable, ideal for various fabrication setups in the UAE, especially where space is limited. Because of their portability, they can be utilized in a variety of settings without requiring complicated setups.

Integration in Modern Manufacturing

The combination of pug cutting machines and laser marking systems creates a comprehensive fabrication solution. In order to fulfill the increasing demands of the market and streamline their operations, manufacturers in the UAE are rapidly implementing both technologies.

Benefits of Combined Implementation

- Streamlined Production

- Reduced production time

- Improved workflow efficiency

- Enhanced quality control

- Better inventory management

- Market Competitiveness

- Higher quality products

- Faster turnaround times

- Increased customization options

- Better traceability

Advantages of Investing in Pug Cutting Machines in the UAE

Investing in pug cutting and laser marking machines offers UAE fabrication businesses a competitive advantage. The combination of these machines provides multiple benefits, including:

- Reduced Lead Times: Pug cutting machines allow for fast, accurate cuts that reduce the time needed for fabrication. When coupled with laser marking, businesses can complete both cutting and marking processes in less time, resulting in quicker project turnaround.

- Increased Precision: By ensuring that materials are cut precisely, pug cutting guarantees that less subsequent processing is required. Laser marking further adds to this accuracy by creating clear, defined markings that enhance product quality.

- Increased Profitability: With faster processing, minimal waste, and precise outputs, businesses in the UAE can increase their profitability. Pug cutting machines, known for low operational costs, and laser marking machines, known for their versatility and efficiency, together contribute to reduced overall costs.

Choosing the Right Pug Cutting Machine Supplier in the UAE

Selecting the correct provider is essential when making a machinery investment. For fabrication businesses in the UAE, find a reputable supplier like Rockwood Machinery, with expertise in pug cutting machines and laser marking machines. We offer reliable support, quality products, and maintenance services to keep your machines operating efficiently.

Conclusion

Pug cutting machines have become indispensable in the fabrication industry, thanks to their precision, versatility, and cost-effectiveness. When combined with advanced tools like laser marking machines, they enable fabrication businesses to deliver top-quality products, enhance production efficiency, and stay competitive. As the demand for high-quality metal fabrication continues to rise in the UAE, investing in pug cutting machines and laser marking technology can be a strategic move for any fabrication business aiming to thrive in the modern market.

For businesses seeking quality pug cutting machines in UAE, partnering with experienced suppliers will ensure that they receive reliable equipment and support to maximize their investment. With these machines in your toolkit, you’re well-equipped to take on the challenges of the dynamic fabrication industry.

To explore further, click: The Pros and Cons of Laser Cutting for Small vs. Large-Scale Manufacturers in UAE