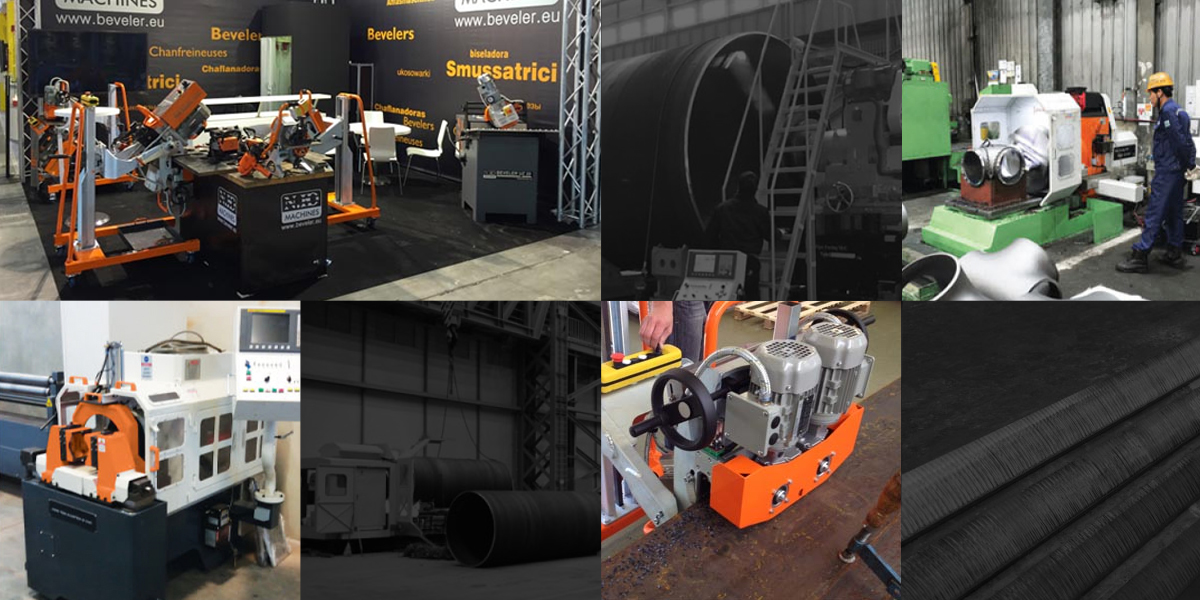

In the metal machining world full of speed and energy, to stay ahead, efficiency, and working have sufficed. Pipe and Plate bevelling machines indeed stand tall amongst others in different industries, giving a huge boost to operational workflows. These machines streamline metal preparation, enhancing welding quality and reducing manual labor. Additionally, industries are also integrating Magnetic lifters to optimize material handling, making workplaces safer and more productive.

Let’s explore the five ways in which Pipe & Plate bevelling machines are transforming industries in the UAE today.

1. Enhanced Precision and Quality in Welding Preparation

One of the biggest advantages of using a Pipe & Plate bevelling machine is the precise preparation of metal edges before welding. Traditional methods often lead to uneven cuts and poor welding joints, which can compromise the strength and integrity of the final product.

With automated bevelling machines, industries in the UAE are experiencing:

- Consistent and precise bevel angles.

- Improved welding penetration and joint quality.

- Minimized material wastage due to accurate cutting.

By achieving high precision, companies can ensure that welded structures last longer, meet international standards, and reduce post-weld rework, saving time and costs.

2. Increased productivity and time-saving benefits.

Manual bevelling is often more tiresome and laboring. However, with advanced Pipe & Plate bevelling machines in UAE, fabrication shops and industrial plants can significantly reduce production time. With these machines, the process of bevelling has been automated: many workpieces can be made ready in no time versus a manual process.

Key benefits include:

- Faster processing times.

- Continuous operation with minimal downtime.

- Higher output with consistent quality.

Industries such as shipbuilding, oil and gas, and heavy engineering benefit from these machines, enabling them to meet project deadlines efficiently.

3. Improved safety and less physical work to be done.

Safety is a major concern in industries, especially while dealing with heavy metal components. Traditional bevelling methods require manual grinding, which exposes workers to risks such as metal shards, sparks, and repetitive strain injuries.

Pipe & Plate bevelling machines eliminate these hazards by:

- Reducing manual handling of sharp edges.

- Minimizing exposure to harmful dust and fumes.

- Offering user-friendly automation that requires minimal intervention.

Additionally, the integration of Magnetic lifters further enhances safety by facilitating easy and secure lifting of metal plates and pipes, reducing workplace injuries and improving handling efficiency.

4. Cost Savings and Reduced Material Waste

Investing in a Pipe & Plate bevelling machine leads to substantial cost savings over time. Manual bevelling often results in material wastage due to errors in cutting angles and uneven edges. Automated machines, however, ensure:

- Precise cutting that maximizes material utilization.

- Reduced need for rework and corrective measures.

- Lower labor costs due to minimal manual intervention.

This not only lets the companies cut on both raw material waste and time spent on whatever production process might be in play but also streamlines production for a profit whilst keeping high quality within range.

5. Versatility for Various Industrial Applications

Pipe & Plate bevelling machines are highly versatile and cater to multiple industrial applications. From aerospace and automotive to shipbuilding and oil refineries, these machines are essential for creating strong, durable metal structures.

Industries using these machines benefit from:

- These machines can work on stainless steel, carbon steel, and different alloys.

- Customization options to meet specific beveling requirements.

- Compatibility with other automation tools like Magnetic lifters in UAE for efficient material movement.

These machines are destined to become an indispensable part of our contemporary metal fabrication setups, given their wide-ranging applications.

Conclusion

The rise of Pipe & Plate bevelling machines is revolutionizing the metalworking industry by enhancing precision, productivity, safety, and cost-efficiency. These machines help businesses improve their welding processes, reduce labor-intensive tasks, and ensure high-quality fabrication. Furthermore, with the addition of Magnetic lifters in UAE, companies can optimize material handling, creating a safer and more efficient work environment.

For businesses in the UAE looking to stay competitive, investing in advanced bevelling machines and magnetic lifting technology is the key to long-term success. By embracing these innovations, industries can achieve faster project completion, superior product quality, and greater operational efficiency.